For professional chefs, choosing the best knife steel is extremely important. The type of steel in a knife greatly influences its sharpness, edge retention, ease of maintenance, and even price.

For example, no matter how well-made a knife is, if the steel doesn’t suit the task or user, it won’t perform to its full potential. Conversely, even an expensive steel is wasted if you can’t take advantage of its properties.

In this article, we’ll explain in detail the characteristics of various steels used in professional Japanese knives – from traditional Yasuki Hagane (the classic Japanese knife steel used in high-end knives) to modern powder high-speed steels, general stainless steels, and even beautiful Damascus steel.

For each type of steel, we’ll analyze its advantages and disadvantages in terms of durability, sharpness, edge holding, rust resistance, ease of sharpening, and cost, and discuss what uses or chefs it is best suited for.

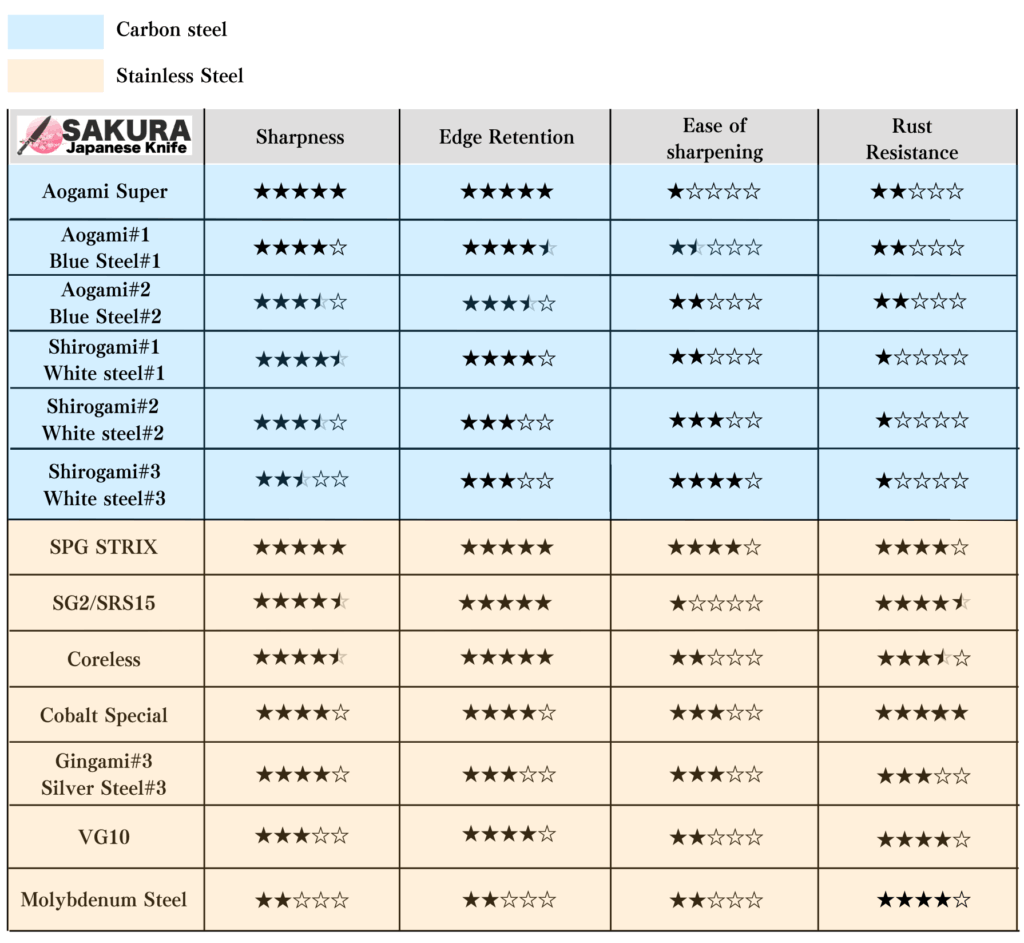

If you don’t have time to read everything, the comparison table below summarizes which steel is suitable for which needs. Feel free to scan the table and jump to any steel that interests you. It outlines what type of steel may be the best fit for different users.

| Usage Purpose / Priority | Recommended Steel | Main Reasons & Features |

|---|---|---|

| Pursuing the ultimate sharpness(Willing to sharpen daily) | – White #1, White #2– Blue #1 (carbon steels) | – Yields an extremely razor-sharp edge, letting you enjoy the traditional keenness of a wa-bocho (Japanese knife).– Ideal for skilled artisans who don’t mind frequent maintenance and sharpening.– Highly prone to rust, requiring diligent wiping and oiling after use. |

| Processing large volumes and wanting less frequent sharpening(Maximize edge retention) | – Blue Super (Aogami Super)– Powder high-speed steels (e.g. SG2 / R2, SRS15, ZDP189, SPG STRIX) | – Exceptionally high hardness and wear resistance, so the edge stays sharp longer even with heavy use.– Reduces the need for sharpening in busy kitchens, improving efficiency.– These steels are expensive and difficult to sharpen, so even professionals must handle with care. |

| Minimizing rust maintenance(Stainless steel for hygiene) | – VG10 (V Gold 10)– Ginsan #3 (Silver #3)– Swedish stainless steel, etc. | – Stainless-based steels that are very rust-resistant, making upkeep easier even in a busy kitchen.– Many high-hardness stainless steels can achieve sharpness close to carbon steel.– Not as effortless to sharpen as softer carbon steel; may still require some work on a whetstone. |

| Keeping costs low for heavy use or many users(Affordable “workhorse” knives) | – Yellow #2– AUS-8 / AUS-10– Molybdenum steel | – Generally inexpensive, easy to work with, and often easy to sharpen.– Many are tough and resistant to chipping, great for hard use or as practice knives for newcomers.– Edge sharpness and holding are lower than premium steels, so these are often used with the expectation of frequent sharpening or eventual replacement. |

| Also prioritizing aesthetic beauty(Showpiece knives, presentation) | – Damascus steel– Coreless Damascus steel | – Gorgeous multi-layered wave patterns that satisfy both performance and the desire to own something visually stunning.– If made with stainless layers, they are rust-resistant and durable as well.– High manufacturing cost; these knives tend to carry premium price tags. |

| Stepping up as skill and experience growWant to progress with sharpening technique | – Beginner: Yellow #2, AUS-8, etc.– Intermediate: Blue #2, VG10, etc.– Advanced: White #1, Blue Super, Powder steels | – Beginners benefit from affordable, easy-to-sharpen carbon or stainless steels to learn the basics.– As you become experienced, you can step up to higher-grade steels to pursue greater sharpness and edge retention.– Advanced users can get the most out of challenging high-end steels, making the investment worthwhile. |

(For comprehensive recommendations on specific knives, see our other articles ranking the best knives in each category.)

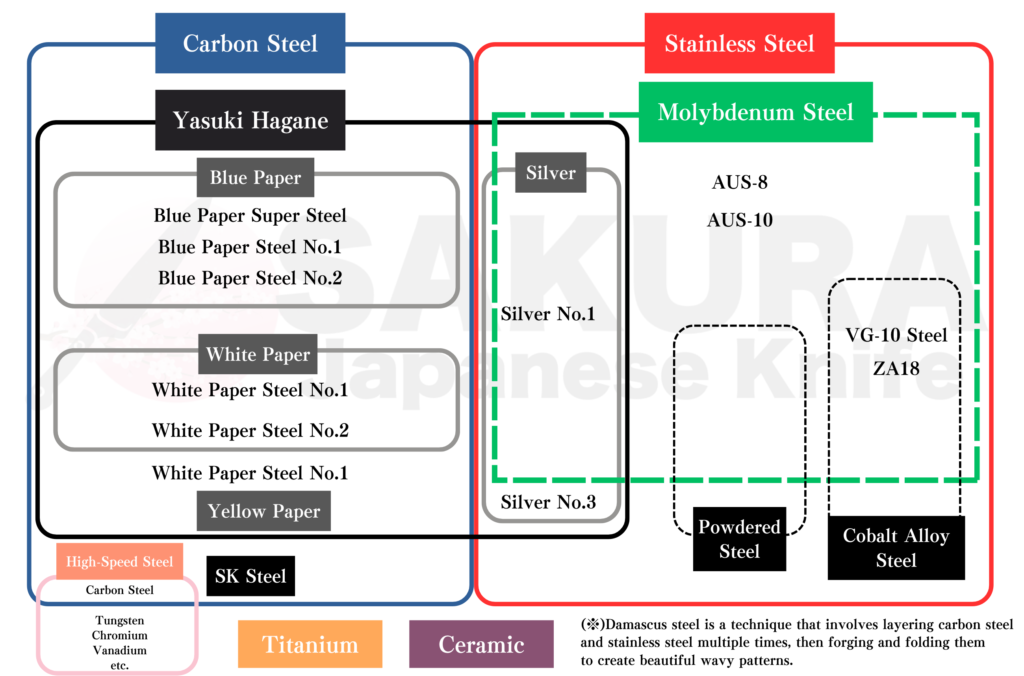

Classification and Overview of Knife Steels

First, if we broadly categorize the main types of steel used in knives, they can be grouped into a few major categories:

Yasuki Hagane Steels (Traditional Carbon Steels)

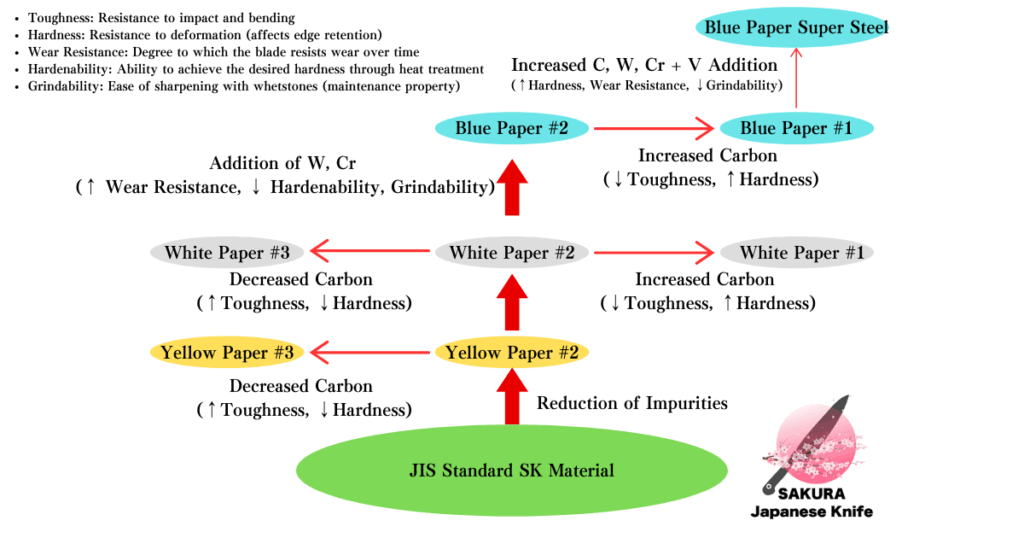

These are traditional high-quality Japanese knife steels produced by Hitachi Metals at the Yasugi plant in Shimane, Japan.

They are often referred to by color-coded names like “Blue Paper,” “White Paper,” “Silver Paper,” “Yellow Paper,” etc.

Powder High-Speed Steels (PM HSS)

These are high-speed tool steels made by powder metallurgy. They have an extremely fine and uniform grain structure.

Stainless Steels

Stainless steels contain at least ~13% chromium (by JIS definition, ≥10.5% Cr) and are characterized above all by their resistance to rust.

Damascus Steels

“Damascus steel” refers to laminated patterned steel made by forging together layers of different steels.

The name comes from analogy to ancient Indian wootz steel (which became famous in Damascus), but modern Damascus knives are mainly valued for their decorative layered patterns.

Each category has its own typical properties and use cases. Below, we will look at each category in detail.

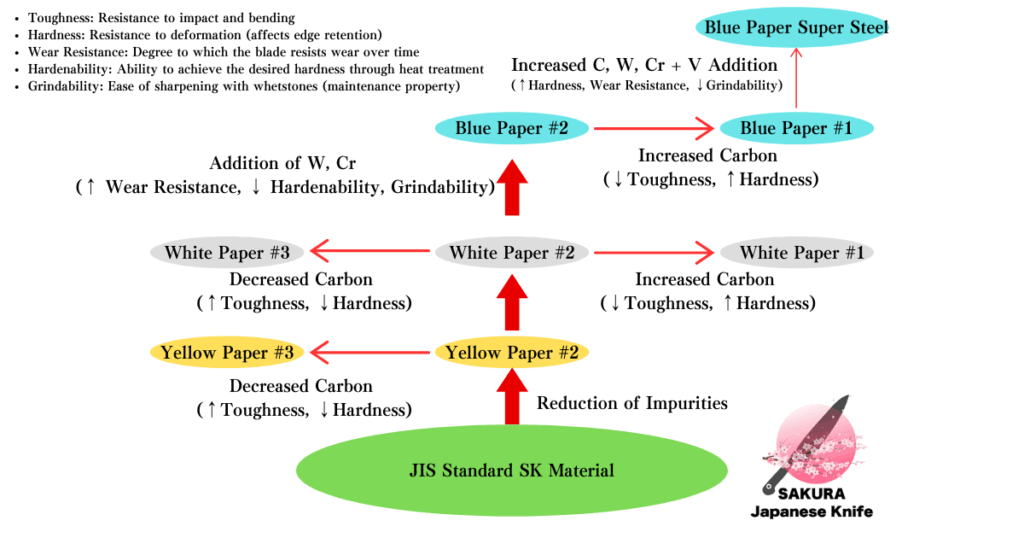

Yasuki Hagane Steels – Details and Characteristics

Yasuki Hagane (Yasuki steel) is a brand of cutlery steel produced at the Hitachi Metals Yasugi plant in Yasugi City, Shimane. These are traditional Japanese high-carbon steels for knives.

They got their nicknames (e.g. “Blue Paper” and “White Paper”) from the colored paper labels once used to identify the steel type on forged blades.

There are many varieties of Yasuki steel with different carbon content and added elements, but the main ones used in knives are as follows:

Blue Paper Steel (Aogami) – including Aogami Super, Aogami #1, Aogami #2

Blue Paper steel (also called Ao-kou or simply Aogami) is a low-alloy steel based on White steel but with chromium and tungsten added. These alloy additions make heat treatment easier and give the blade more toughness, making it less prone to chipping.

Blue steel is known for its high hardness, excellent sharpness, and long edge holding, while being less chip-prone than White steel and achieving more uniform hardness. This means in settings where you’re cutting a large amount of food, it stays sharp longer and doesn’t require sharpening as frequently as White steel.

The downside of blue steel, being a carbon steel, is that it rusts easily, so diligent maintenance is a must. Its high hardness also makes it harder to sharpen, and getting the absolute best performance from it requires skill. Additionally, the steel itself is costly – especially knives made from Blue #1 or Blue Super tend to be very expensive.

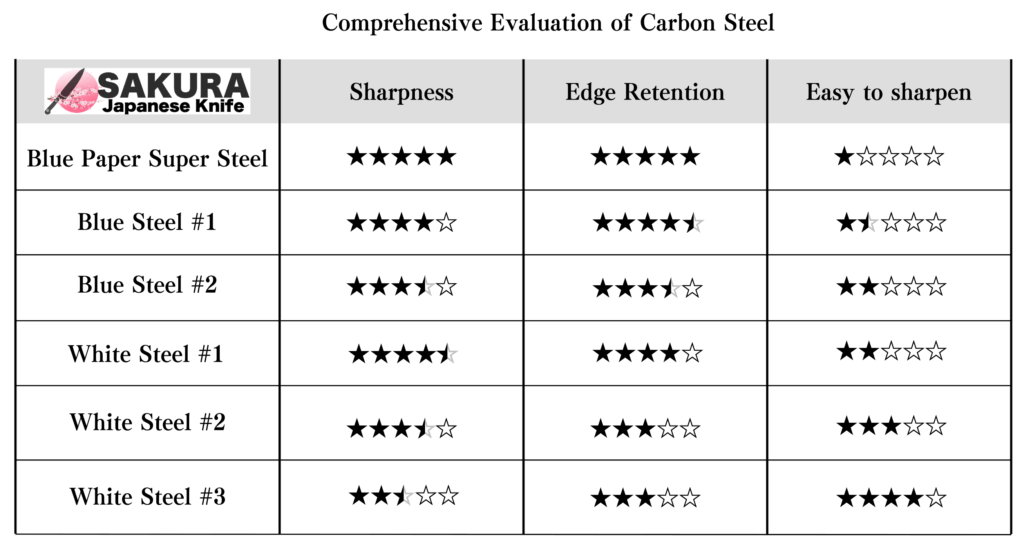

Below is a comparison of the characteristics of Blue Super, Blue #1, and Blue #2:

| Blue Super | Blue #1 | Blue #2 |

|---|---|---|

| Main Composition | – C ~1.4–1.5%– Cr ~0.3–0.5%– W ~2.0–2.5%– V ~0.3–0.5%– Mo: trace | – C ~1.3–1.4%– Cr ~0.2–0.5%– W ~1.5–2.0%– V: trace– Mo: trace |

| Merits | – Achieves very high hardness (~HRC 64).– Outstanding edge retention; stays sharp for a long time.– Can handle heavy-duty chopping with less frequent sharpening. | – Not as extreme as Blue Super, but still extremely high hardness (~HRC 63).– Edge sharpened to an outstanding level of keenness.– More resistant to chipping, with decent toughness. |

| Demerits | – Extremely difficult to sharpen due to the high hardness.– Very prone to rust (high carbon content), so thorough cleaning after use is mandatory.– High alloy content makes the steel expensive (knives are premium-priced). | – Still prone to rust; must be cleaned and dried diligently after use.– Sharpening is challenging (geared toward experienced carbon-steel users).– While slightly cheaper than Blue Super, it’s still a very expensive steel. |

| Best Suited For | – Professionals who prioritize edge retention above all.– Chefs confident in their sharpening skills.– Situations where frequent resharpening is not possible (long work sessions). | – Experienced chefs who prioritize maximum sharpness.– Those who will use the knife intensively with regular light sharpening (e.g. primarily using traditional wa-bocho).– Slightly easier to handle than Blue Super, but still requires a high skill level. |

Blue Super – Contains a lot of alloying elements, the hardest and best edge-holding of the blue steels. However, it’s extremely difficult to sharpen and knives are very premium-priced. Suited for scenarios like processing large volumes of food continuously, but demands significant maintenance effort.

Blue #1 – When sharpened, its edge is among the very sharpest. Not as extreme as Blue Super but still requires advanced sharpening skills. A favored steel for getting the absolute best edge on traditional Japanese knives, and loved by chefs who are particular about their blades.

Blue #2 – Slightly lower in carbon, so a bit tougher and easier to handle than Blue #1. Still provides very high sharpness and edge retention, yet is easier to sharpen – a big plus. Highly regarded for its balance of “excellent sharpness” and everyday practicality, it offers great performance for its cost and is commonly used in primary knives of both Japanese and Western styles.

White Paper Steel (Shirogami) – White #1 and White #2

White Paper steel (also called Shiro-kou or Shirogami) is a high-purity carbon steel made from very low-impurity satetsu (iron sand). It contains almost no alloying elements, and is classified into #1, #2, #3 based on carbon content (generally #1 has the highest carbon and is hardest).

Its hallmark is an extremely keen cutting edge. Chefs who “prioritize sharpness above all” have loved white steel for generations. In particular, White #2 is known as one of the most commonly used steels among professionals.

The biggest merit of white steel is its unparalleled sharpness – its purity means a finely sharpened edge can be incredibly keen, considered the pinnacle in the world of wa-bocho. It also has a great sharpening feel; it responds very well to whetstones and is relatively easy to sharpen (Note: White #1 is a bit harder to sharpen due to higher hardness, but White #2 and #3 sharpen about as easily as an average carbon steel). White steel is also a bit more affordable than the blue steels, offering good performance for the price.

On the other hand, susceptibility to rust is its biggest downside – thorough cleaning and drying after use is absolutely required. Also, because of the high hardness, it can be prone to chipping; White #1 in particular demands very careful heat treatment and sharpening due to its extreme hardness. White steel knives also have poorer edge retention compared to blue steel, meaning they need more frequent sharpening. Overall, it’s a steel that assumes you’ll do regular maintenance.

Below is a summary of the features of White #1 and White #2:

| White #1 | White #2 |

|---|---|

| Main Composition | – C ~1.3–1.4%(Ultra-high-purity carbon steel with minimal impurities; essentially no alloy elements added.) |

| Merits | – When fully sharpened, it achieves an extremely razor-sharp edge.– Highly regarded as a “top-grade traditional knife steel.”– With almost no alloying elements, it delivers a very delicate, smooth cutting feel. |

| Demerits | – Very strict heat treatment and high hardness make it prone to chipping.– Extremely rust-prone; meticulous maintenance after use is a must.– Priced on the high side. |

| Best Suited For | – Chefs who are skilled at sharpening and constantly pursue the very sharpest edge.– Professionals willing to sharpen their knife diligently every day to keep peak performance.– Those who prioritize the absolute sharpness of the edge (e.g. for sashimi or other delicate Japanese cuisine). |

(Note: White #3 steel has even lower carbon than White #2, making it easier to sharpen and more forgiving (tougher) for beginners, though its sharpness is slightly less. It’s sometimes used in entry-level wa-bocho, but this article focuses on White #1 and #2.)

White #1 – A steel with very high carbon content. With masterful heat treatment and sharpening, it can deliver the “ultimate sharpness.” However, it’s among the more challenging carbon steels to sharpen and is quite brittle and rust-prone. It’s favored by only the most skilled chefs, particularly for tasks like sashimi slicing or ultra-fine work where it truly shines.

White #2 – Since it has a bit less carbon than White #1, it’s slightly tougher and more user-friendly. It still offers outstanding sharpness and edge retention, and the big advantage is that it’s easier to sharpen than White #1. Ideal for chefs seeking an “amazing sharp edge” with a more manageable balance for everyday use.

Yellow Paper Steel (Kigami), e.g. Yellow #2

Yellow Paper steel (also called Ki-gou) is a carbon steel with more impurities than White steel, sometimes described as “half made from satetsu.” In other words, if you removed the impurities from Yellow steel, you’d get White steel. Because Yellow has lower purity, it is cheaper and suitable for mass production compared to White steel.

There are grades from #2 through #5 by carbon content, but for knives the primary one used is Yellow #2. Its hardness is lower than White or Blue steel, and the blade is softer with less cutting performance. However, its defining feature is that it’s easy to sharpen.

Below we focus on Yellow #2:

| Details | |

|---|---|

| Steel Name | Yellow #2 (Medium-carbon Japanese cutlery steel) |

| Main Composition | • ~1.0 % Carbon (C)• Essentially no deliberate alloying elements (may contain trace Mn, etc.) |

| Merits (Pros) | • Very cost-effective → cheaper than White/Blue steels• Slightly softer → much easier to sharpen• Higher impurity content boosts toughness → less brittle, better chip-resistance• Forgiving steel that tolerates heavy prep work |

| Demerits (Cons) | • Cannot match the extreme sharpness or edge longevity of premium White/Blue/powder steels• Plain carbon steel → rusts easily; demands diligent care• May feel lacking if pushed to high-performance cutting levels |

| Best Suited For | • First-time carbon-steel users or those practicing sharpening skills• Cooks needing a tough, practical blade for large-volume prep• Budget-minded users wanting carbon-steel sharpness• Rough work settings (fish processing, butchery, heavy prep) where toughness & cost outrank ultimate sharpness |

(Note: There is no official “Yellow #1” grade; Yellow steel starts at #2. In this article we primarily discuss Yellow #2 as the most relevant grade.)

In summary, Yellow #2 does not hold an edge as long as higher-grade steels and will need more frequent maintenance. And as a carbon steel, it will rust if not cared for, so cleaning and drying after use is essential. Performance-wise, it may feel insufficient for the very high standards of some professionals, but if you prioritize toughness, durability, and easy upkeep, it’s a very user-friendly steel.

Ginsan Steel (Silver Paper #3 Steel)

Ginsan-ko, or Silver Paper #3 (commonly called Ginsan or Gin-san), is a stainless cutlery steel made by Hitachi Metals. It’s essentially White steel with over 13% chromium added to make it stainless, achieving a combination of rust resistance and the kind of sharpness you’d expect from a carbon steel.

Its hardness can be raised to levels comparable to carbon steel, making it a long-valued steel for rust-resistant wa-bocho (traditional Japanese knives). A big feature of Ginsan is that it’s easier to sharpen than many other stainless steels.

With a hardness around HRC 60, it has excellent wear resistance. But compared to other stainless steels of similar hardness (like VG10), Ginsan contains fewer additives, which is why it grinds more smoothly on a whetstone.

In practice, people say “While Ginsan may not match VG10 in sheer hardness or wear resistance, it’s easier to resharpen than VG10, which is why many chefs favor it.” It delivers extremely sharp cutting performance—often said to be on par with White steel carbon knives. And being stainless, it offers high rust resistance, making daily maintenance easier.

| Details | |

|---|---|

| Steel Name | Ginsan #3 (Silver #3, a stainless Japanese cutlery steel) |

| Merits (Pros) | • Delivers sharpness close to White steel yet remains stainless → strong rust-resistance• High hardness and comparatively easy to sharpen; “bites” into whetstones smoothly• Satisfies professional cutting performance & durability demands• Better chip-resistance and overall toughness than many ultra-hard steels |

| Demerits (Cons) | • Rich in alloying elements → costly to manufacture → knives are premium-priced• Edge retention a touch below Blue steels and some powder steels (still excellent by normal standards)• Stainless, but not totally stain-proof; high carbon means post-use care is still required |

| Best Suited For | • Pros who want “White-steel sharpness in a stainless package.”• Intermediate-to-advanced users who enjoy hand-sharpening but want lower rust worries• Chefs handling lots of fish (yanagiba, deba, etc.) needing both keen edge & corrosion resistance• Anyone seeking a high-performance wa-bocho for long-term use with easier maintenance |

Those are the main steels in the Yasuki steel category. In summary: White steel gives the best sharpness but is suited for craftsmen who don’t mind intense sharpening and upkeep;

Blue steel prioritizes edge retention and is geared toward kitchens wanting to sharpen less often; Yellow steel is an affordable, easy-to-use entry-level choice; and Ginsan (Silver #3) is a rust-resistant, pro-friendly high-end stainless steel.

Next, let’s look at the powder high-speed steels that have gained attention in recent years.

Powder High-Speed Steels (PM HSS) – Details and Characteristics

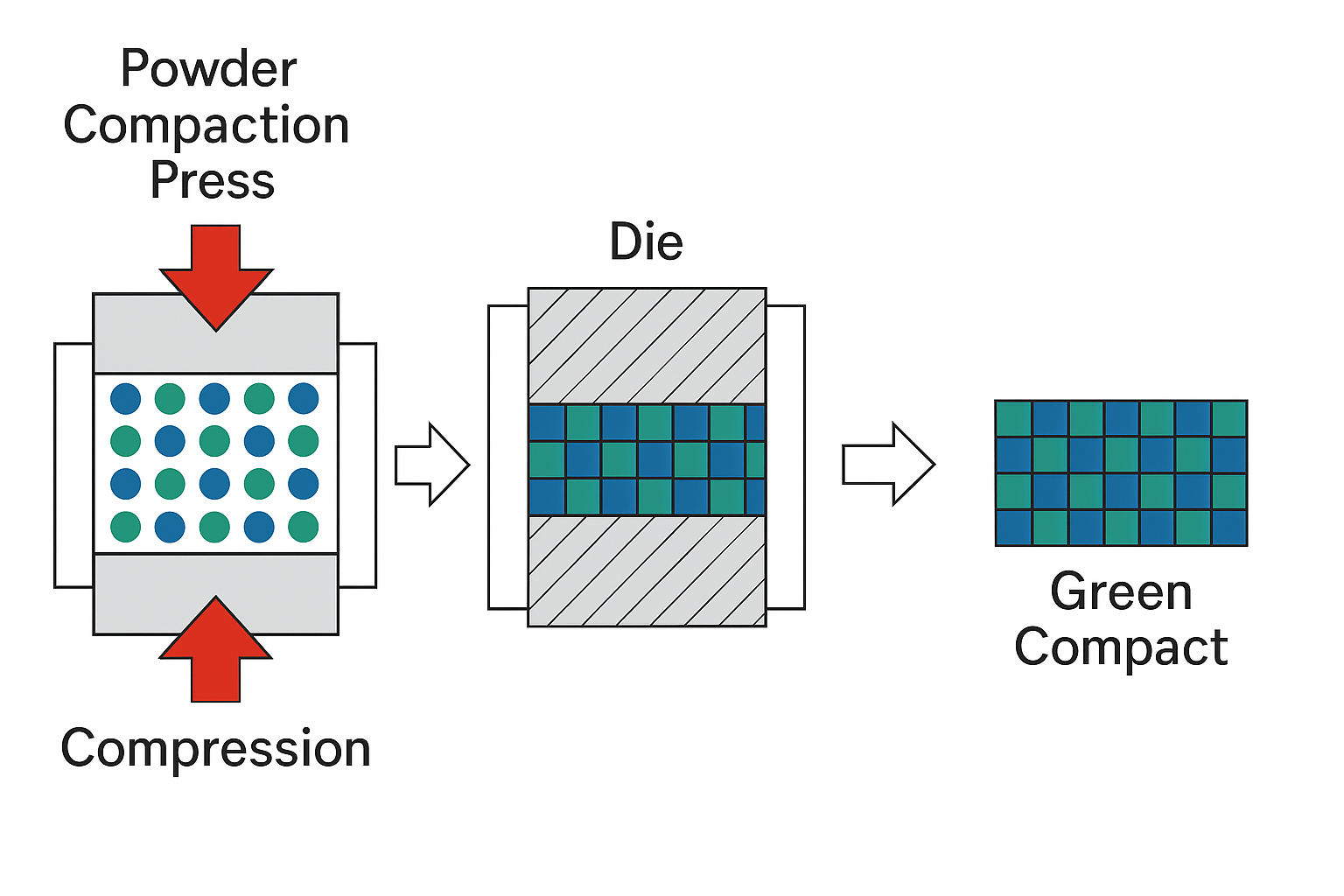

Powder high-speed steel (powder metallurgy high-speed steel) is a steel made by powder metallurgy from conventional high-speed tool steel. Because it’s produced by sintering fine metal powders, its microstructure is extremely uniform with very finely dispersed carbides.

As a result, compared to conventional cast (ingot) steels, wear resistance, toughness, and cutting performance are greatly improved, yielding a very high-performance blade steel.

In particular, by incorporating very high levels of carbon and alloy elements (such as tungsten, molybdenum, vanadium, etc.), these steels achieve extremely high hardness so that the edge can resist wear for an exceptionally long time.

On the other hand, the drawbacks are that they are difficult to sharpen (because they’re so hard) and the steel itself is very expensive. Below, we explain some representative powder high-speed steels in order.

ZDP189

ZDP189 is a next-generation ultra-high hardness powder stainless steel developed by Hitachi Metals. It has about 3.0% carbon and ~20.0% chromium – an ultra-high carbon, high-chromium composition – and is produced by powder metallurgy.

Thanks to this composition and process, it achieves extremely high hardness – it can be hardened to about HRC 67, an astonishing level that is among the highest for knife steels. This gives it phenomenal wear resistance; in other words, its edge holding ability is extraordinary.

ZDP189’s edge retention is truly in a class of its own. Even when slicing large quantities of food or repeatedly cutting very hard ingredients, the edge remains sharp. Its rust resistance is also maintained at a stainless-steel level, thanks to the 20% chromium content. However, due to the high hardness, this steel is notoriously difficult to sharpen.

When hand sharpening, it takes a long time to form an edge. Some even say it’s “one of the most difficult steels to sharpen by hand.” Its toughness is actually decent for such a high-alloy steel, but again, because the hardness is so extreme, you have to be careful about chipping.

It’s also extremely expensive, and knives made with ZDP189 tend to be rare and command very high prices.

| Details | |

|---|---|

| Steel Name | ZDP189 (Powder-metallurgy stainless steel) |

| Main Elements | • ~3.0 % Carbon (C)• ~20.0 % Chromium (Cr) |

| Merits (Pros) | • Can reach ≈ HRC 67 → extremely hard• Superb edge retention; stays sharp even under heavy, continuous use• Stainless → high rust resistance• Greatly reduces resharpening frequency for professionals |

| Demerits (Cons) | • Very hard to sharpen – diamond stones / advanced technique recommended• Extra-hard edge is relatively brittle → chipping risk if misused• High material & processing costs → knives are premium-priced• Requires ultra-precise heat treatment → only a few makers offer it |

| Best Suited For | • Pro chefs handling long shifts or large prep volumes• Sushi bars, luxury restaurants where a razor-sharp edge is critical• Users with access to professional sharpening or advanced gear• Those who prioritize peak performance over cost and enjoy experimenting with top-tier steel |

SG2 (Super Gold 2, a.k.a. R2)

SG2 is a powder stainless steel made by Takefu Special Steel (formerly Daido Steel). Some knife makers market it under the name R2. While not quite as extreme as ZDP189, it still offers very high hardness and wear resistance. Thanks to the fine microstructure from powder metallurgy, SG2 also manages to retain a certain degree of toughness despite its high hardness.

Rust resistance is also excellent, with ~15% chromium content – plenty for a stainless – making SG2 popular as a steel that provides “high hardness yet strong rust resistance” in knives.

SG2 offers an extremely high level of balance between sharpness and edge holding. Fine vanadium carbides distributed in the steel help prevent edge wear and keep the blade sharp for a long time. (Below is a summary of SG2’s key characteristics.)

SG2 (Super Gold 2 / R2)

| Details | |

|---|---|

| Steel Name | SG2 (Super Gold 2 / R2 — powder-metallurgy stainless steel) |

| Main Elements | • C ≈ 1.3–1.4 %• Cr ≈ 14–15 %• Mo ≈ 2.5–3 %• W ≈ 1.2 %• V ≈ 2 % |

| Merits (Pros) | • High hardness (≈ HRC 63–65) & wear resistance → superb edge retention• Stainless base → strong rust-resistance & food-safe hygiene• PM process yields very fine, uniform carbides → good balance of sharpness & toughness• More forgiving than ultra-hard ZDP189; easier to achieve a stable edge |

| Demerits (Cons) | • Still slow/hard to sharpen — high hardness grinds slowly on stones• Expensive: PM production & machining costs drive up knife price• Though tougher than ZDP189, it’s still more chip-prone under shock/torque than softer steels |

| Best Suited For | • Intermediate–advanced users comfortable with sharpening• Professional kitchens needing long-lasting sharpness with stainless convenience (e.g., sushi bars, upscale restaurants)• Chefs wanting a high-end powder steel without the extreme sharpening difficulty of ZDP189 |

SRS15

SRS15 is a powder stainless steel used by certain makers (e.g. Hori Hamono in Kochi); it’s said to have been developed by Kobe Steel (exact composition is not officially disclosed).

It reaches about HRC 63–65 hardness, roughly on par with SG2. However, due to differences in alloy design, it’s praised as a steel that “achieves high hardness while maintaining a good balance of toughness and workability.”

SRS15 (Powder Stainless Steel)

(All composition values are approximate, as the manufacturer hasn’t released official figures.)

| Details | |

|---|---|

| Steel Name | SRS15 (Powder-metallurgy stainless steel) |

| Main Elements (approx.) | • C ≈ 1.5 %• Cr ≈ 13 %• Mo ≈ 2.75 %• W ≈ 1.25 %• V ≈ 1.5 % |

| Merits (Pros) | • Very high hardness (≈ HRC 63–65) → long-lasting edge retention• Somewhat easier to sharpen than SG2; can achieve a smooth, refined edge• High chromium → strong rust resistance• Balanced toughness for a PM steel → lower chipping risk than many ultra-hard steels |

| Demerits (Cons) | • Still slow to sharpen compared with ordinary stainless• High production & machining costs → knives are expensive and not widely available• Limited supply; not mass-produced• Less forgiving under heavy impact or twisting than simple carbon steels |

| Best Suited For | • Professionals / advanced users with solid sharpening skills• Kitchens requiring long-lasting sharpness and stainless convenience• Chefs who want SG2-class performance with slightly easier sharpening• Users willing to pay a premium for state-of-the-art powder steel performance |

SPG STRIX (Super Gold STRIX)

SPG STRIX is a new-generation powder stainless steel developed by Takefu Special Steel. It was designed specifically as a cutlery steel with the goal of “high hardness while being as easy to sharpen as carbon steel.”

Traditionally, powder steels that reach around HRC 67 hardness were known to be very hard to sharpen on a whetstone. The developers of SPG STRIX noted that carbon steels of similar hardness aren’t as difficult to sharpen, so they focused on strengthening the metal matrix itself. By reinforcing the steel matrix, they achieved both high hardness and ease of sharpening.

In short, whereas conventional powder steels relied on a large amount of hard carbides to boost hardness, SPG STRIX achieves extreme hardness by making the matrix itself harder and tougher, rather than overloading on carbides.

| Details | |

|---|---|

| Steel Name | SPG STRIX (Super Gold STRIX — powder-metallurgy stainless steel) |

| Key Features | • Achieves ≈ HRC 65 hardness• Reinforced steel matrix engineered for added toughness & sharpenability |

| Merits (Pros) | • Ultra-hard (≈ HRC 65) yet comparatively easy to sharpen for a PM steel• Outstanding edge retention and razor-sharp potential• Edge can be honed extremely finely—sharpness rivals top carbon steels• Matrix-focused design offers better chip-resistance than many other powder steels |

| Demerits (Cons) | • Very costly to manufacture → knives are extremely expensive• Few brands/models use it → limited availability• Still less easy to sharpen than plain carbon or mid-hardness stainless steels (though easier than most PM steels)• New material → limited long-term track record & user feedback |

| Best Suited For | • Professionals/experts seeking state-of-the-art powder-steel performance• Chefs wanting carbon-steel-like sharpening feel with PM-steel hardness• Top-tier kitchens (sushi bars, haute cuisine) needing long-lasting razor edges for high-volume prep• Knife enthusiasts willing to pay a premium for the latest technology with no compromises |

Since SPG STRIX is still very new, it’s hard to fully evaluate its long-term performance. However, based on its specs, it’s arguably one of the most well-balanced and impressive steels available.

All of the powder high-speed steels above achieve an almost outlandish level of edge retention, but accordingly they also come with high cost and high sharpening difficulty.

In other words, they are ideal if your goal is to “reduce sharpening frequency to the absolute minimum” or “minimize the hassle of rust management,” but using them to their full potential requires appropriate skill and a good maintenance regimen.

Next, let’s move on to steels that are more forgiving in terms of maintenance: stainless steels.

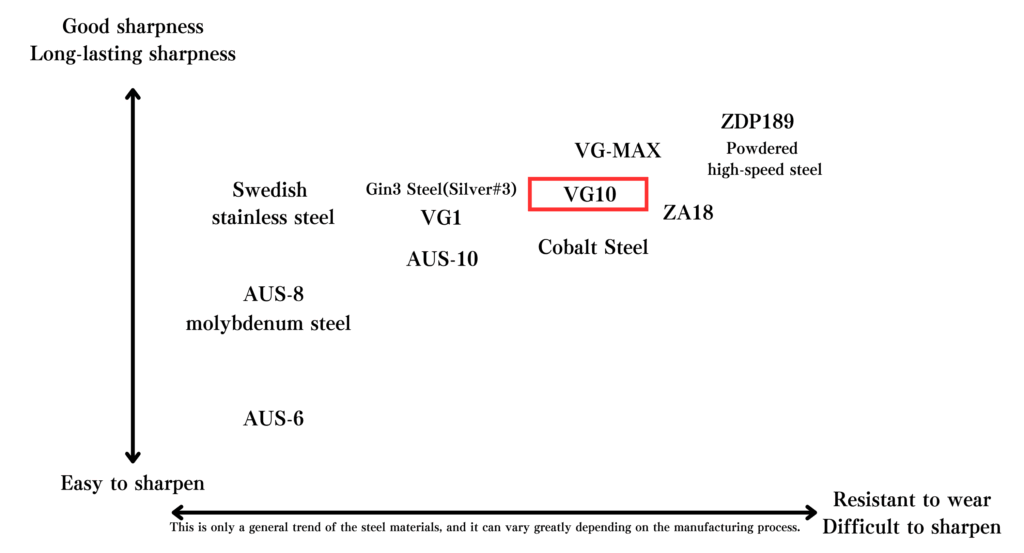

Stainless Steels – Details and Characteristics

Stainless steel is generally defined by a chromium content of 13% or more (≥10.5% in JIS standards) and is characterized by being highly resistant to rust. Professional kitchen knives use a variety of stainless steels; in this section we’ll cover some of the most representative ones.

Overall, stainless steels are much easier to care for than carbon steels. The trade-off is that achieving the same level of ultra-fine sharpness as a carbon steel can sometimes require more effort or technique. However, recent years have seen the development of many high-performance stainless steels that combine excellent sharpness with rust resistance, and they are widely used even in professional settings.

VG10 (V Gold 10)

VG10 is a high-end stainless cutlery steel developed by Takefu Special Steel.

Knives made of VG10 are known for having great sharpness, excellent edge retention, and also being resistant to chipping, a very well-balanced performance profile. This is because the added cobalt in VG10 increases the strength of the steel, allowing it to achieve high hardness while still maintaining toughness.

In fact, VG10 is often described as “a popular steel that cuts very well, has excellent wear resistance, and a tough blade that isn’t prone to chipping.”

| Details | |

|---|---|

| Steel Name | VG10 (V-Kin 10 — premium stainless steel from Takefu) |

| Main Elements | • C ≈ 1.0 % • Cr ≈ 15 % • Co ≈ 1.5 % • Mo ≈ 1 % • V ≈ 0.2–0.3 % |

| Merits (Pros) | • Excellent balance of sharpness, edge retention, and toughness• High chromium → strong corrosion resistance• Cobalt addition delivers high hardness (≈ HRC 60) and chip-resistance• Can be honed to a keen edge—nearly rivals carbon steels while staying stainless |

| Demerits (Cons) | • Costly steel; knives are priced higher and made by limited manufacturers• Ultimate edge not quite as fine as top carbon steels (e.g., Blue #1)• Sharpening is easier than most stainless but still slower than plain carbon steels |

| Best Suited For | • Professional chefs wanting high sharpness & edge life with simplified rust care• Makers/users of stainless versions of traditional wa-bocho (yanagiba, deba, etc.)• Intermediate–advanced users comfortable with routine sharpening and maintenance |

Coreless Steel (Coreless Damascus Steel)

Coreless steel refers to a laminated steel that has no separate core layer.

In a conventional Japanese knife, a hard core steel is sandwiched between layers of softer iron or stainless steel (a three-layer construction). In coreless steel, however, two different hard steels—such as VG10 and VG2—are stacked alternately, so the entire blade, from edge to spine, is made of hard steel.

Marketed under Takefu Special Steel’s registered trademark “CORELESS®,” the material is produced with a new process that refines carbides to an ultra-fine scale.

By laminating and hot-rolling dozens of layers, it achieves both a uniform composition and a striking wood-grain pattern. Technically it is a type of Damascus steel, but because it lacks a core, the whole blade can be quenched, giving it high hardness and strength. A typical example is the VG10/VG2 alternating laminate, which reaches roughly HRC 60 and offers excellent toughness.

With no soft core, the blade maintains uniform hardness from edge to side. This makes it less prone to micro-chipping, and even after repeated sharpening the edge remains in hard steel layers, improving resistance to wear. The carbide refinement further boosts wear resistance, and the pattern appears more vivid than in ordinary Damascus.

Cutting performance is as keen as the VG10 component would suggest, and edge retention is likewise strong. In practical terms, it behaves like a “mono-steel with a pattern,” providing a stable material free from concerns about core separation or delamination.

| Details | |

|---|---|

| Overview | A laminate with no separate core: alternating layers of hard steels (e.g., VG-10 + VG-2) are forged together so the entire blade—edge to spine—is hard steel. |

| Merits | • Uniform hardness along the whole blade, even after heavy thinning.• No soft iron appears when you re-grind, so sharpness and appearance last longer.• Usually uses multiple stainless layers → very corrosion-resistant and durable.• Produces a sharper, more vivid pattern than conventional Damascus. |

| Demerits | • Extremely costly to manufacture → knives sit in the premium price band.• Few makers and models → harder to source.• Because every layer is hard steel, grinding removes more metal and the pattern can change.• Still a new technology, so long-term real-world data are limited. |

| Best Suited For | • Chefs who want top-tier sharpness, durability, and aesthetics in one knife.• Open-kitchen or live-cooking settings where blade beauty matters.• Professionals/enthusiasts who want stainless convenience plus artistic Damascus looks—and are happy to invest in a long-term “forever” blade. |

Because it marries striking aesthetics with practical performance, this steel is favored not only as a primary workhorse knife in professional kitchens but also by presentation-focused users—such as chefs who cook in front of guests and instructors who demonstrate techniques in cooking classes.

AUS Series Steels (AUS-8, AUS-10)

AUS-8 and AUS-10 are part of a series of stainless knife steels produced by Aichi Steel in Japan. They typically contain around 13–14% chromium plus molybdenum and vanadium, with the number indicating carbon content (approximately 0.8% C for AUS-8, and ~1.0% C for AUS-10).

AUS-8 reaches about HRC 57–59 hardness and AUS-10 about HRC 59–61. These hardness levels are a bit lower than higher-end steels like VG10, but in exchange AUS steels are more affordable and easier to sharpen, which is why they are commonly used in mass-market and mid-range Japanese knives.

Coreless Steel (Coreless Damascus Steel)

| Category | Details |

|---|---|

| Overview | A laminate with no separate core: alternating layers of hard steels (e.g., VG-10 + VG-2) are forged together so the entire blade—edge to spine—is hard steel. |

| Merits | • Uniform hardness along the whole blade, even after heavy thinning.• No soft iron appears when you re-grind, so sharpness and appearance last longer.• Usually uses multiple stainless layers → very corrosion-resistant and durable.• Produces a sharper, more vivid pattern than conventional Damascus. |

| Demerits | • Extremely costly to manufacture → knives sit in the premium price band.• Few makers and models → harder to source.• Because every layer is hard steel, grinding removes more metal and the pattern can change.• Still a new technology, so long-term real-world data are limited. |

| Best Suited For | • Chefs who want top-tier sharpness, durability, and aesthetics in one knife.• Open-kitchen or live-cooking settings where blade beauty matters.• Professionals/enthusiasts who want stainless convenience plus artistic Damascus looks—and are happy to invest in a long-term “forever” blade. |

AUS Steels (AUS-8 & AUS-10) — Comparison Table

AUS steels are a series of stainless knife steels made by Aichi Steel. They contain roughly 14 % chromium plus molybdenum and vanadium, and are classified by carbon content—e.g., “8” for about 0.8 % C and “10” for about 1.0 % C.

- AUS‑8 attains roughly HRC 57–59

- AUS‑10 reaches roughly HRC 59–61

Although these hardness levels are slightly below that of the higher‑grade VG10, AUS steels are less expensive and easier to sharpen, which is why they are commonly used in mid‑range kitchen knives.

| AUS-8 | AUS-10 | |

|---|---|---|

| Main Composition | • C ≈ 0.8 %• Cr ≈ 13–14 %• Mo / V: trace• Lower carbon → hardness ~HRC 57–59 | • C ≈ 1.0 %• Cr ≈ 13–14 %• Mo / V: trace• Higher carbon → hardness ~HRC 59–61 |

| Merits | • Inexpensive, great cost-performance.• Stainless → rust-resistant, easy upkeep.• Mid-range hardness → fairly easy to sharpen.• Tough edge, resists chipping. | • Same rust-resistant stainless base.• Extra carbon gives higher hardness, better edge life than AUS-8.• Sharpening feel almost identical to AUS-8—still easy.• Only slightly pricier than AUS-8, far cheaper than high-end steels. |

| Demerits | • Can’t match the razor edge or longevity of carbon or premium PM steels.• In tough pro kitchens you’ll need frequent touch-ups.• Wears fast on the stone—risk of over-thinning. | • Still below top carbon / PM steels for ultimate sharpness.• Medium wear-resistance → regular sharpening required under heavy use.• May feel lacking if you demand ultra-long edge life. |

| Best Suited For | • Beginners–intermediates needing a practice or daily knife.• Heavy prep or rough work where toughness & low cost matter.• Food chains / culinary schools that must equip many knives on a budget. | • Users wanting more bite & edge life than AUS-8 while keeping ease of use.• Cooks who can maintain their own knives but don’t want to pay for VG10-class steel.• A versatile “one-knife” option for a wide user range. |

Although AUS steels cannot rival premium alloys for absolute sharpness or edge longevity, their strong corrosion resistance and low-maintenance nature make them invaluable in professional settings—whether as backup knives or in kitchens that keep large fleets of blades in rotation.

Consequently, they’re well-suited to apprentice and mid-level chefs. They’re ideal when you want to outfit yourself with several knives on a budget or need a forgiving steel for sharpening practice.

Used more often in Western-style than in traditional Japanese knives, AUS steels appear in a wide range of general-purpose blades—santoku, gyuto, petty knives, and more. They’re popular not only among professionals but also in upscale home kitchens, and they make an excellent “first serious knife” for many users.

Molybdenum Steel (Molybdenum Vanadium Steel)

“Molybdenum steel” isn’t a strictly defined term, but generally in Japan it refers to stainless cutlery steels with molybdenum and vanadium added.

A classic example is the German steel X50CrMoV15 (around 15% chromium, small amounts of molybdenum & vanadium, ~0.5% carbon), which is used in many Western-style kitchen knives.

In Japan, similar steels are often labeled “molybdenum-vanadium steel” and are commonly used for household kitchen knives. Hardness is moderate (around HRC 56–58), and these steels are characterized by being very rust-resistant and highly tough.

(Image: Molybdenum steel knife)

Molybdenum steel knives excel in ease of handling and safety. Since their hardness isn’t very high, the blade is somewhat soft and ductile, making it resistant to chipping or breaking. You can even hit bones or hard foods without the blade cracking, which speaks to their toughness.

They are also very resistant to rust – some knives made of molybdenum steel are even dishwasher-safe – which shows how easy they are to maintain. In terms of cutting performance, the edge is usually more utilitarian than razor-fine; in fact, many knives in this category have a relatively thick edge for durability. Edge retention is average, but because the steel is soft, re-sharpening on a whetstone is very easy.

| Details | |

|---|---|

| Steel Name | Molybdenum Steel (a.k.a. Molybdenum-Vanadium Steel) |

| Main Elements(typical grade, e.g. X50CrMoV15) | • C ≈ 0.5 %• Cr ≈ 13–15 %• Mo ≈ 1 %• V = trace |

| Merits (Pros) | • Very rust-resistant → hygienic, worry-free use• Tough and pliable → resists chipping / breaking• Relatively inexpensive → good for equipping large kitchens• Medium hardness → quick, easy resharpening & touch-ups |

| Demerits (Cons) | • Can’t achieve the razor edge or long edge life of high-carbon / powder steels• Edge dulls faster under heavy, prolonged use• Many moly knives are relatively thick → less ideal for ultra-fine, delicate cuts |

| Best Suited For | • Large-scale food-prep settings (catering, schools, hospitals, chain restaurants)• Beginners or users who prefer minimal sharpening & rust care• Commercial kitchens needing cost-effective yet reliable knives• Pros who want a durable “beater” knife they can use hard without worrying about chips |

In terms of pure cutting performance, molybdenum steels don’t match up to the top-tier steels (carbon or powder stainless), and they do require more frequent sharpening.

And of course, being stainless doesn’t mean you can ignore maintenance – they will rust eventually if neglected, so you should still clean and dry them after use. That said, if you place a premium on toughness, durability, and easy maintenance, these steels are extremely practical and user-friendly.

Swedish Stainless Steel

In the Japanese knife industry, when we refer to “Swedish steel,” we typically mean stainless steels made by the Swedish company Sandvik.

The representative examples are 13C26 (equivalent to AEB-L) and 19C27 (equivalent to AEB-H). These were originally developed for razor blades and scalpels, and are extremely high-purity steels with very low impurity content.

Swedish stainless steel is famous for the blade taking an exceptionally keen edge. Because the grain structure is so fine and uniform, you can hone the edge to an extremely sharp apex, and its cutting performance is said to rival that of carbon steel.

| Details | |

|---|---|

| Steel Name | Swedish Stainless Steel |

| Main Examples | • Sandvik 13C26 (C ≈ 0.6 – 0.7 %, Cr ≈ 13 %)• Sandvik 19C27 (C ≈ 0.95 %, Cr ≈ 13 %) |

| Key Features | Produced with extremely low impurity levels → high-purity, high-toughness stainless steels |

| Merits (Pros) | • Ultra-fine grain → can be sharpened to a razor-like, very acute edge (originally developed for razor blades)• Strong rust resistance while offering a sharpening feel close to carbon steel• Hardness ≈ HRC 59 – 61 → good balance of edge retention and toughness• High toughness allows thin grinding without making the blade too fragile → resists chipping and keeps a delicate edge for a long time |

| Demerits (Cons) | • Relatively expensive due to the high-purity metallurgical process• Limited availability—fewer brands and models compared with steels like VG10• Does not reach the ultra-high hardness or extreme edge life of some powder steels (though practically sufficient for most users) |

| Best Suited For | • Intermediate–advanced users seeking extreme sharpness plus stainless convenience• Cooks who want stainless versions of traditional Japanese knives with a carbon-steel-like edge (e.g., yanagiba, sujihiki)• Professionals or enthusiasts who perform their own sharpening and want to maximize steel performance |

Because of its low impurity content, Swedish steel feels wonderful on the whetstone, much like sharpening a carbon steel. It’s highly praised by pros and knife aficionados who prioritize sharpness.

While it might not boast the same mind-boggling edge retention as super-alloy powder steels like ZDP189 or SG2, in everyday use it holds an edge more than well enough.

It produces a very high-quality, refined cutting edge. The main considerations are its somewhat higher cost and the fact that it’s not as commonly found on the market, so you have to seek it out.

Damascus Steel – Details and Characteristics

Damascus steel refers to a pattern-welded steel made by forge-welding together many layers of different steels.

The name comes from the legendary ancient Indian wootz steel (which was traded through Damascus, giving it fame), but modern Damascus kitchen knives are primarily valued for their decorative layered wave patterns and aesthetic appeal.

At the same time, a layered structure can bring some functional benefits. In knives, typically there are two approaches: one is a hard core steel sandwiched between layers of soft iron or stainless (a common “clad” construction), and the other is a coreless Damascus where even the core is part of the layered pattern (all-steel damascus).

Either way, the multiple layers of metal, revealed when the blade is ground and etched, produce a unique rippling pattern – each Damascus knife has a one-of-a-kind beautiful motif.

The performance of a Damascus knife is determined by the core material and steel used. For example, if you have a Damascus knife with a VG10 core and soft iron outer layers, its cutting and edge-holding properties will essentially be those of VG10.

However, the layered construction does lead to some general tendencies, which we’ve summarized below:

| Details | |

|---|---|

| Merits (Pros) | • Rust-resistant: Stainless layers cover much of the surface, so the knife as a whole is less prone to corrosion.• High durability: Hard core + softer cladding balance brittleness and toughness, yielding a strong yet resilient blade.• Beautiful wave patterns: Distinctive layered look conveys luxury and fine craftsmanship.• Good cutting performance: Hard core supplies high edge hardness, while softer layers absorb shocks and reduce chipping—much like a Japanese sword’s construction. |

| Demerits (Cons) | • Often expensive: Multi-layer materials and forge-welding labor raise the price.• Pattern can fade when sharpened: Heavy side-grinding during thinning can dull or remove the pattern.• Performance hinges on the core steel: Lamination alone doesn’t guarantee sharpness or edge life; heat-treat and core alloy are decisive.• Some blades are thick: Extra layers to showcase the pattern may increase blade thickness and cutting resistance. |

Using a hard core steel with soft layered sides results in an edge that is hard, supported by a more flexible spine – a very rational design also seen in the construction of Japanese swords (shinogi-zukuri style). This design allows the knife to cut smoothly through both soft and hard materials alike.

And, of course, we must highlight the gorgeous appearance. The mystical wave patterns, often compared to wood grain or flowing water, make each blade unique, giving it the aura of a one-of-a-kind work of art.

Thanks to their beauty and status appeal, many professionals will own at least one special Damascus knife. Using it in an open kitchen in front of customers, or on TV or in magazines, is sure to draw attention.

On the other hand, in kitchens where a flashy-looking knife isn’t necessary, there’s no practical need to choose Damascus. Ultimately, it comes down to whether you value both aesthetics and function in your knife. For those who see the value in that combination, a Damascus steel knife can be the perfect choice.

Comparison Table and Overall Evaluation of Each Steel

Below, we’ve compiled a comparison table of the main steels discussed in this article, along with an overall evaluation. (This is essentially the same summary chart shown at the beginning.)

We evaluate six attributes that professional chefs tend to consider most: Durability (toughness), Sharpness, Edge Retention, Rust Resistance, Ease of Sharpening, and Price Range. The relative tendencies are rated as “Very High ◎, High ○, Medium △, Low ✕.”

(Scroll to see the full table on smaller screens.)

| Steel | Durability(Toughness) | Sharpness | Edge Retention | Rust Resistance | Ease of Sharpening | Price Range |

|---|---|---|---|---|---|---|

| Blue Super | △ (hard but somewhat brittle) | ◎ (extremely sharp) | ◎ (exceptionally long-lasting) | ✕ (very rust-prone) | ✕ (extremely difficult to sharpen) | ◎ (very expensive) |

| Blue #1 | △ (hard, chipping caution) | ◎ (highest level of sharpness) | ◎ (very long-lasting) | ✕ (rust-prone) | ✕ (difficult to sharpen) | ◎ (very expensive) |

| Blue #2 | △ (hard but a bit tougher) | ○ (sharp) | ○ (long-lasting) | ✕ (rust-prone) | △ (somewhat hard to sharpen) | ○ (high cost) |

| White #1 | △ (hard, can chip easily) | ◎ (extremely sharp) | ○ (above average) | ✕ (rust-prone) | △ (difficult to sharpen) | ◎ (very expensive) |

| White #2 | △ (standard toughness) | ◎ (very sharp) | △ (average) | ✕ (rust-prone) | ○ (relatively easy to sharpen) | ○ (medium cost) |

| Yellow #2 | ○ (very tough) | △ (adequate, but average) | △ (somewhat low) | ✕ (rust-prone) | ◎ (very easy to sharpen) | ◎ (inexpensive) |

| Ginsan #3<br*(Silver 3)* | ○ (comparatively tough) | ○ (sharp) | ○ (good) | ◎ (highly rust-resistant) | ○ (easy to sharpen) | ◎ (very expensive) |

| ZDP189 | △ (hard, watch for brittleness) | ○ (sharp) | ◎ (astonishingly long-lasting) | ◎ (highly rust-resistant) | ✕ (extremely hard to sharpen) | ◎ (very expensive) |

| SG2 / R2 | △ (hard, fine-grained with some toughness) | ○ (sharp) | ◎ (long-lasting) | ◎ (highly rust-resistant) | △ (difficult to sharpen) | ◎ (very expensive) |

| SRS15 | △ (hard but well-balanced) | ○ (sharp) | ◎ (long-lasting) | ◎ (highly rust-resistant) | △ (slightly easier to sharpen) | ◎ (very expensive) |

| SPG STRIX | ○ (hard yet tough) | ○ (very sharp) | ◎ (long-lasting) | ◎ (highly rust-resistant) | ○ (easy to sharpen for a PM steel) | ◎ (very expensive) |

| VG10 | ○ (hard with good toughness) | ○ (sharp) | ○ (long-lasting) | ◎ (rust-resistant) | △ (a bit time-consuming to sharpen) | ○ (high cost) |

| Coreless Damascus | ○ (tough throughout) | ○ (sharp) | ○ (long-lasting) | ◎ (rust-resistant) | △ (pattern may fade with sharpening) | ◎ (very expensive) |

| AUS-10 | ○ (plenty tough) | △ (standard) | △ (medium) | ◎ (rust-resistant) | ◎ (easy to sharpen) | △ (moderate) |

| AUS-8 | ◎ (extremely tough) | △ (standard) | △ (medium) | ◎ (rust-resistant) | ◎ (easy to sharpen) | ◎ (inexpensive) |

| Molybdenum Steel | ◎ (exceptionally tough) | △ (practical sharpness) | △ (medium) | ◎ (rust-resistant) | ◎ (very easy to sharpen) | ◎ (inexpensive) |

| Swedish Stainless | ○ (high toughness) | ◎ (extremely sharp) | ○ (good) | ◎ (rust-resistant) | ◎ (very easy to sharpen) | ○ (high cost) |

| Damascus Steel (general) | ○ (structurally tough) | * (depends on core) | * (depends on core) | ○ (rust-resistant) | △ (must mind pattern when sharpening) | ○ (expensive) |

* Sharpness and edge retention for Damascus steel depend on the core material used (e.g. VG10, Blue steel, etc.).

As the table shows, each steel has its own strengths and weaknesses. For example, if you seek “the ultimate sharpness,” White #1 or Swedish steel are rated ◎ in sharpness – but you also need to be prepared for challenging sharpening and diligent rust management.

On the other hand, if “rust-proof, maintenance-free” convenience is your top priority, then Molybdenum steel or AUS-8 would be suitable – but their sharpness and edge retention are inferior to the higher-end steels. For a professional, the important thing is to choose a steel that matches your skill level and your specific use case.

Conclusion: Which Knife Steel is Best for Professional Chefs?

Given all of the above, it’s impossible to declare one single “best knife steel” for every professional chef. Each type of steel has different pros and cons, and the ideal choice varies with the chef’s skill, the nature of the work, and personal preferences. In conclusion, we offer the following guidelines:

For chefs confident in their sharpening technique, seeking the absolute best sharpness

Steels like White #1 and Blue #1 are recommended. If handled correctly, these can deliver unparalleled sharpness and let you experience the very essence of fine knife performance.

However, you must be willing to devote time and effort to sharpening and upkeep. By paying constant attention to your knife (sharpening it daily or as needed), you’ll be able to draw out its maximum potential.

For busy kitchens where you want to reduce time spent resharpening

If you’re processing large quantities of ingredients and need an edge that lasts, Blue steel (especially Blue Super or Blue #1) or a powder high-speed steel (like SG2, SRS15, etc.) is ideal.

These steels’ edges dull very slowly, even during heavy use, which can improve work efficiency by cutting down on sharpening interruptions.

They’re also good for those who aren’t fond of sharpening. Just remember, “low maintenance” doesn’t mean “no maintenance” – once you do notice the sharpness starting to drop, it’s important to take the time to resharpen and restore the edge before it deteriorates too much.

If you want to prevent rust as much as possible and lighten maintenance

Your best bet is to choose from the stainless steel family. Among these, VG10 stands out for its superb balance of sharpness, edge holding, and toughness, and it’s a steel loved by many professionals.

Ginsan (Silver #3) is also very rust-resistant and easy to sharpen, making it popular with chefs who prefer traditional-style knives (it allows wa-bocho like sashimi knives or deba to have stainless properties).

If you want to keep the feel of a classic Japanese knife but avoid rust, a wa-bocho made of Ginsan steel is a strong candidate (many sashimi and deba knives use it successfully).

Meanwhile, for Western-style knives, steels like Molybdenum steel or AUS-8 are highly rust-resistant and easy to handle, so they suit environments where hygiene and easy care are top priorities.

For newcomers or those still practicing their knife skills (and sharpening skills)

Steels that are easy to sharpen and inexpensive – such as Yellow steel (#2) or AUS-8 – are well-suited.

These materials can tolerate a bit of rough handling and are easy to fix if you make mistakes, and they’re perfect for learning and practicing on a whetstone.

Start with a user-friendly steel to build up your fundamental skills with the knife. Once you’re comfortable, you can consider stepping up to higher-end steels like Blue or White steel to pursue greater sharpness and edge retention.

For pros who also value the knife’s beauty and status

In this case, a Damascus steel knife is highly attractive. It not only offers solid performance but also the joy of owning a beautiful piece of craftsmanship – which can be a great motivator and source of pride.

High-quality Damascus knives are also practically excellent (often rust-resistant and long-lasting in sharpness if made with good core steel).

To maintain the pattern you’ll need to be a bit careful in how you sharpen (so you don’t grind off the design), but the effort is well worth it for the visual appeal you get in return.

Overall

The “most suitable steel” is ultimately the one that best matches your individual needs as a chef. In choosing a professional knife, the key is to be clear about your own skill level, the nature of your work, and what you value most (for example, is it maximum sharpness, or minimal maintenance?). Then select a steel that aligns with those factors.

For instance, if you’re willing to sharpen your knife every day to chase the absolute sharpest edge, a carbon steel might be your best fit. If you’d rather sacrifice a bit of sharpness for the sake of a knife that won’t rust, a stainless steel would be better. If you want a compromise of both, a powder steel or a laminated (composite) steel could be the answer.

Keep in mind that the more expensive a steel is, generally the higher the performance – but only if you can fully take advantage of it. Consider whether your skills and routine will draw out what that steel has to offer.

In a professional kitchen, the truly best knife steel is the one that is easy for you to work with and reliably gets the job done. Find a knife (and steel) that suits you, take care of it properly, and use it to its fullest – that will be one of the greatest assets in your culinary arsenal.

Comments