Ceramic knives have gained a devoted following among both professional chefs and outdoor adventurers. At first, you might wonder: “A knife that isn’t made of metal – can it really cut?” Many had the same doubt. But once you hold a ceramic knife and make your first slice, the skepticism fades. These blades feel feather-light yet incredibly sharp, offering a cutting experience that often leaves newcomers amazed.

In this comprehensive guide, we’ll explore exactly what ceramic knives are, their unique advantages and disadvantages, how they compare to traditional steel knives, tips for care and maintenance, and insights from experts in the kitchen and in the field. Whether you’re a sushi chef looking for the cleanest cuts or an outdoor enthusiast needing a rust-proof tool, read on to discover what ceramic knives can do for you.

GENSAKU

GENSAKUGENSAKU (Craftsman): “I’ve forged steel for 40 years, but ceramic is a different beast. Imagine a blade made from the same advanced ceramics used in aerospace – that’s what you get here. We mold ultra-hard zirconia powder, fire it above 1000°C to form a blade harder than steel, then grind it to a razor’s edge. No iron at all, yet it cuts like a dream.”

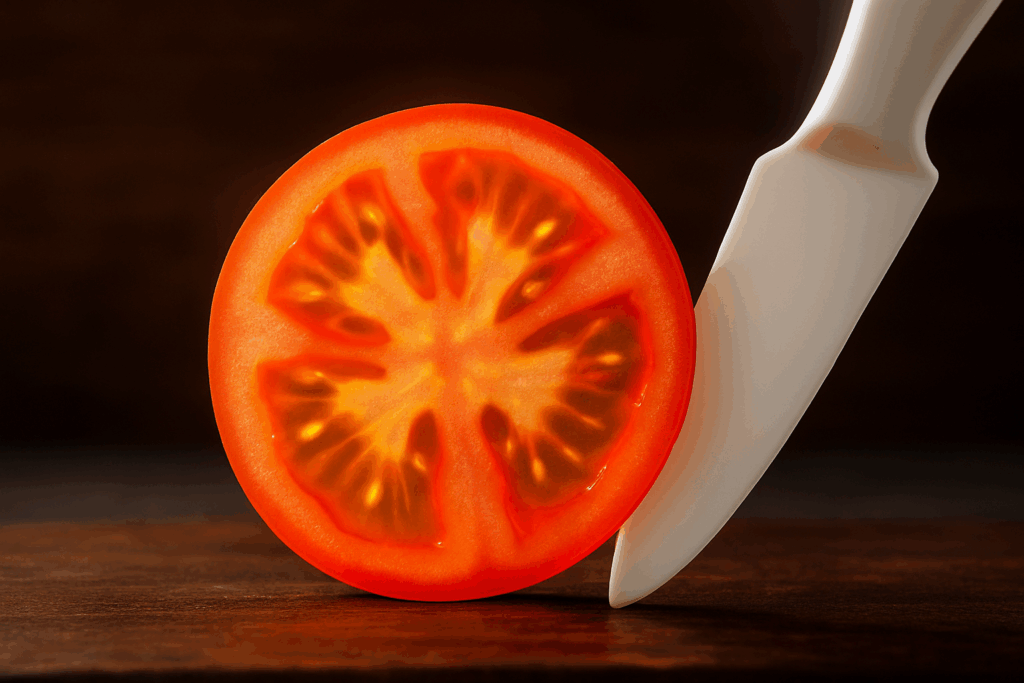

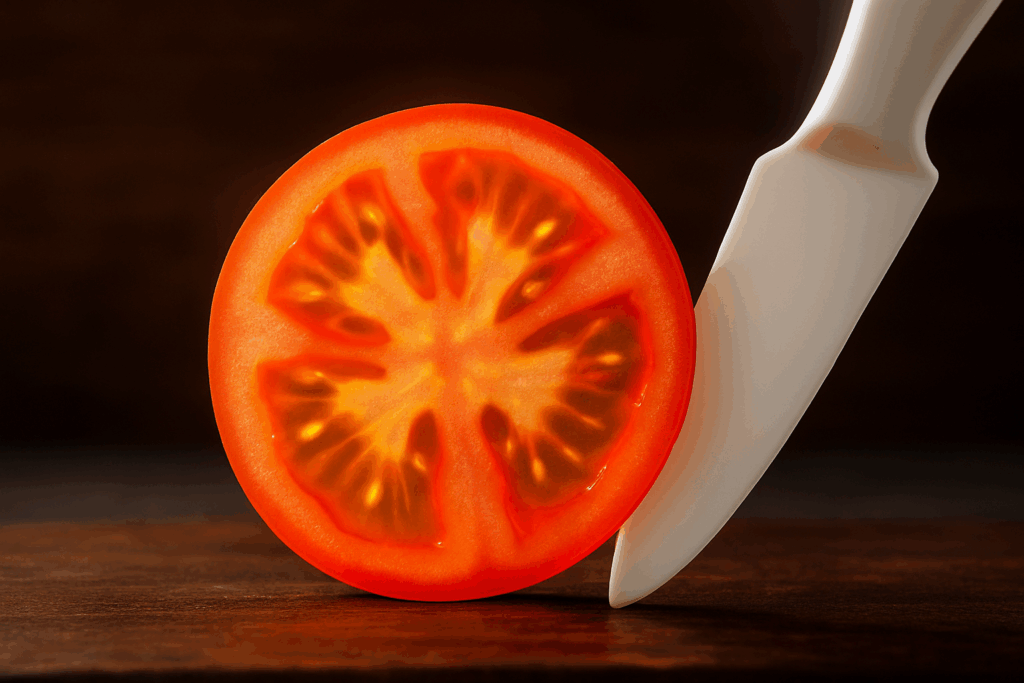

YUKIKO (Chef): “I admit, when I first picked up a ceramic kitchen knife, I said, ‘Wow, this is so light… can it actually slice?’ But the moment I cut into a tomato, it glided right through. I was sold – it was surprisingly sharp and effortless.”

In this guide, we’ll cover the basics of ceramic knives, their pros and cons (especially vs. steel blades), some special uses (tactical and outdoor applications), how to maintain them, and a look at Kyocera – the brand that pioneered these blades. Let’s dive in.

What Is a Ceramic Knife? (Basic Overview)

A ceramic knife is a knife with a blade made not from steel, but from a high-tech ceramic, typically zirconium dioxide (zirconia). The blade is created by compressing zirconia powder and firing it in a furnace (a process called sintering) until it forms an extremely hard, dense ceramic material.

In fact, ceramic knife blades score about 8.5 on the Mohs hardness scale, whereas ordinary steel is around 4.5 and even the hardest knife steels are around 7.5–8. (For reference, diamond is 10 on that scale.) This exceptional hardness means a well-made ceramic blade can be ground to a very fine, sharp edge and will keep that edge far longer than steel.

GENSAKU: “Zirconia ceramic is so hard that sharpening it requires diamond tools. But that hardness lets us give it an edge that stays razor-sharp much longer than any steel. And since there’s zero metal, it will never rust.”

Ceramic knives are also lighter than steel knives. Zirconia is dense, but a ceramic blade can be made thinner and doesn’t require a heavy metal bolster. Many ceramic kitchen knives weigh about half of a comparable steel knife. The first time you hold one, the lack of heft is striking – as Yukiko described, you might literally say “fuwah! (light as air)” in surprise.

Despite having no metal, a ceramic knife can indeed be extremely sharp. The material’s hardness allows the factory to hone the edge very keenly. Users often note how easily a ceramic knife sails through tomatoes, peppers, and other produce with minimal resistance, yielding clean cuts. The blade’s edge is so hard that it resists wear: you won’t need to sharpen a ceramic knife nearly as often as a steel one. In tests, ceramic blades have stayed sharp 10 times longer than typical steel blades before needing sharpening.

However, this same hardness comes with a trade-off: brittleness. Unlike steel, which has a degree of flexibility or “toughness” (it might bend or dull under stress), a ceramic blade is rigid and can chip or crack if mishandled. Think of it like glass: hard but fragile. If you twist a ceramic knife or drop it on a hard floor, it could break or develop a chip in the edge. This means ceramic knives require a bit more care in use (we’ll cover care tips later).

In summary, a ceramic knife is a lightweight, ultra-hard, non-metallic blade. It offers unprecedented sharpness and edge retention with the bonus of never rusting, but it demands careful handling due to its brittleness. Next, we’ll look at all the benefits such a knife brings – and the limitations to be aware of.

Advantages of Ceramic Knives

Ceramic knives bring several unique advantages to the cutting board (and the campsite) that set them apart from traditional steel knives. Chefs who use them often praise how they make prep work easier, and outdoor users appreciate their no-fuss durability in challenging environments. Below is a quick summary of key advantages, and we’ll explore each in detail:

| Advantage | What It Means | Benefit to You |

|---|---|---|

| Rust-Proof | Blade contains no iron, so it will not corrode or rust even when exposed to acids, moisture, or salt. | No more worrying about drying or oiling your knife. You can cut acidic foods (tomatoes, lemons) or even leave the knife in a damp sink without fear of rust spots. Low maintenance and peace of mind for busy chefs or humid outdoor conditions. |

| Ultra-Lightweight | Typically half the weight of an equivalent steel knife. Zirconia blades are very hard and thin, and handles are often lightweight plastic. | Less fatigue during long cutting sessions. Chefs can chop for hours with less strain on the wrist and shoulder. Backpackers and campers enjoy a lighter load – every ounce counts on the trail. |

| Long-Lasting Sharpness | Ceramic’s hardness (~8.5 Mohs) means the edge stays sharp 10× longer than steel in use. It’s also immune to acids or juices that might dull steel edges. | Consistently razor-sharp performance with minimal upkeep. Your knife slices cleanly every time, making prep faster and more enjoyable. Fewer sharpening sessions needed – perhaps a quick touch-up once a year or even less. |

| Hygienic & Non-Reactive | Completely non-metallic blade won’t react with foods. It never imparts a metallic taste or odor, and it resists staining. Ingredients like onions or garlic won’t linger on the blade. | Pure, clean flavor in delicate foods. Fruits and veggies won’t brown as quickly after cutting (no iron to trigger oxidation). Easy cleaning – just a quick rinse, since nothing really sticks. Great for cutting fruits, salads, or even serving slices directly, as the blade won’t affect the food’s taste or color. |

Let’s delve a bit deeper into these advantages:

Rust-Proof Convenience

One of the biggest selling points of ceramic knives is that they never rust. Traditional steel knives (even stainless steel) contain iron, which will oxidize and form rust if not cared for. By contrast, ceramic blades have zero metal, so you can literally leave a wet ceramic knife out all night and come back to an untarnished blade. For chefs, this means no more fretting over wiping down the blade immediately after cutting acidic ingredients. Cut through all the tomatoes, citrus, or vinegary pickles you want – a ceramic knife laughs it off with no corrosion.

YUKIKO: “Sometimes I’m juggling dinner and two kids – I’ve accidentally left my ceramic chef’s knife in the sink until the next morning. With my old steel knife, I’d panic about rust spots. With ceramic? No rust, no problem. It’s one less thing to worry about when cleaning up.”

For outdoor enthusiasts, the rust-proof nature is a dream. You can take a ceramic knife on a boat, out in the rain, or into humid jungles without concern. Unlike a carbon steel blade that might corrode if you neglect to dry it by the campfire, a ceramic blade is completely impervious to the elements. This makes ceramic knives excellent for fishing trips (no saltwater corrosion) and survival kits in wet climates. They are also non-magnetic, an added bonus in situations where you want to avoid magnetism or detection (more on that in the tactical section).

Ultra-Lightweight Handling

Pick up a ceramic kitchen knife and you might do a double-take – it feels almost like a toy because it’s so light. In truth, that lightweight build is a major advantage for frequent knife users. A well-made 6-inch ceramic chef’s knife can weigh on the order of only a few ounces. For example, some folding ceramic pocket knives weigh as little as 2 ounces!

In the kitchen, this reduces fatigue. If you’re chopping vegetables for an extended period or filleting a dozen fish, a lighter knife means less strain on your hand and arm. Professional chefs appreciate how a lighter blade can be flicked around quickly with less effort, making repetitive tasks more comfortable. Home cooks with arthritis or limited hand strength also find ceramic knives easier to handle for extended prep, since the blade practically floats through cutting motions.

On the outdoor side, a lightweight knife is a huge plus for hikers and campers. You can slip a ceramic knife into your pack and barely notice it.

GENSAKU: “Back when I climbed mountains, we counted every gram. A ceramic knife for camp cooking – that’s a luxury I’d carry, since it hardly adds weight.”

Every reduction in weight helps when you’re miles from civilization, and a ceramic blade delivers cutting capability at minimal heft.

Just be mindful: that low weight is due to the absence of dense metal, but it also means the knife might not have the same balance or blade-heavy feel as a steel knife. Some chefs need a little time to adjust their technique because there’s less weight doing the work. Once you get used to it, though, the maneuverability is excellent.

Long-Lasting Sharpness

Perhaps the most celebrated advantage of ceramic knives is their edge retention. These blades stay sharp far longer than steel knives. Why? It circles back to hardness: on the cutting edge, a harder material resists wear. When you slice with a knife, microscopic bits of the edge deform or wear away over time. Steel (even hard steel) is softer than ceramic, so it wears faster. A quality ceramic knife can go months to years without needing re-sharpening, even with daily use on fruits, vegetables, and boneless meats.

Testing by independent labs found that ceramic blades can maintain a usable edge about 10 to 12 times longer than typical steel blades. In practical terms, many users report that their ceramic kitchen knives still cut paper-thin slices of tomato after a year of regular use, whereas a steel knife would have needed several sharpening sessions in that time.

Ceramic’s edge retention really shines when cutting produce and other soft foods. For example, slicing through fibrous vegetables or acidic fruits can dull a steel knife quickly (acid can microscopically corrode steel and plant fibers abrade it). A ceramic blade, being chemically inert and harder than the fibers, doesn’t dull as easily. You’ll notice you can make dozens of clean carrot cuts or paper-thin cucumber slices and the ceramic edge remains keen.

YANAGAWA (Sushi Chef): “In my sushi work, I need a knife that’s always sharp for ultra-clean fish slices. I’ve found I can do hundreds of sashimi slices with a ceramic knife and the edge still feels like new. With steel, I’d be touching up the edge on a stone much more often to keep that level of sharpness.”

It’s worth noting that while ceramic knives come extremely sharp, the absolute sharpness out-of-the-box can be comparable to high-end steel knives, but perhaps not surpass a master-sharpened carbon steel edge. However, the big difference is the consistency of that sharpness over time. A steel knife might take a finer edge initially, but it will dull much sooner and require honing/sharpening to stay keen. Ceramic knives eliminate that frequent maintenance – they remain “sharp enough to shave” with minimal upkeep.

The bottom line: a ceramic knife stays sharper longer, which means cleaner cuts and less hassle for you. You’ll enjoy effortlessly slicing ripe tomatoes, crusty bread, or tender chicken breast with a blade that seems to never quit.

Clean and Hygienic Cutting

Ceramic knives are also prized for being chemically inert and easy to keep clean. The ceramic material won’t react with foods or liquids. This has a few important benefits:

- No Metallic Taste or Discoloration: Some cooks notice a metallic tang or slight discoloration when using steel knives on certain fruits (for example, apples or lettuce browning). With a ceramic knife, there are no metal ions to trigger those reactions. Your lettuce stays crisp and green longer, and your apples or avocados won’t brown as quickly after slicing.

- Odor Resistance: Ever cut garlic or onions with a steel knife and notice the blade retains the smell? Ceramic blades are less porous and don’t hang onto odors. This means you can mince garlic, rinse the knife, and then immediately slice an apple without fear of “garlic apple” flavor. For a chef like Yukiko who might cut pungent ingredients then delicate ones, this is a blessing.

- Stain Resistance: Foods like beets, turmeric, or berries can stain steel blades (or at least the patina on carbon steel). Ceramic knives, especially those with white blades, tend to resist staining. They maintain a clean, new appearance with minimal effort. A quick wash with dish soap, and even the reddest beet juice comes off.

- Easy Cleaning: Since ceramic is non-reactive and doesn’t rust, you don’t need special cleaners or oils. A simple soap and water rinse is all that’s required for everyday cleaning. Also, because the blade is so smooth and hard, foods are less likely to stick to it compared to some metal knives. Just be careful in the dishwasher: while the ceramic blade itself isn’t bothered by detergent or water, bumping against other dishes or utensils could chip it. Hand-washing is recommended to be safe.

YUKIKO: “When preparing meals for my children, I care about hygiene and flavor. My ceramic knife doesn’t transfer smells, so I can go from chopping herbs to slicing fruit without a second knife. And I love that it doesn’t rust or get weird spots – it always looks perfectly clean, which gives me peace of mind when cooking for the family.”

For professional kitchens, the hygienic aspect also means less cross-contamination. Some sushi chefs use ceramic knives for tasks like cutting sashimi or fruits for garnish, where purity of flavor is crucial. Similarly, in outdoor use, a ceramic knife won’t spark or cause any strange tastes if you’re cleaning game or preparing food in the field.

Overall, the non-reactive nature of ceramic knives ensures that what you taste is only the food, not the knife. This purity, combined with ease of cleaning, makes ceramic an attractive choice for anyone who values flavor integrity and low-maintenance tools.

Disadvantages of Ceramic Knives

No knife is perfect for every situation, and ceramic knives come with their own set of limitations and precautions. It’s important to understand these drawbacks to use ceramic blades effectively and safely. Here’s a summary of the key disadvantages (and how to manage them):

| Disadvantage | Details / Caution | How to Mitigate |

|---|---|---|

| Brittle – Chips or Cracks Easily | Ceramic is hard but not tough – the blade can chip or shatter if dropped or struck on a hard surface. Cutting into hard bones or frozen foods can cause the edge to chip or break. | Use the knife only on appropriate foods (no bones, no frozen solids). Handle with care: don’t twist or pry with it. Always use a soft cutting board (wood or plastic, not glass or marble). Store the knife in a block or sheath so it won’t get knocked around. |

| Not for Heavy-Duty Use (Limited Applications) | A ceramic knife cannot replace a steel knife for tough tasks. It won’t cut through bones, hard squash skin, or wood without likely damage. It’s also not suited for prying or twisting motions. | “Use the right tool for the job,” as chefs say. Reserve your ceramic knife for slicing fruits, veggies, boneless meats, and light duties. Keep a good steel chef’s knife or cleaver on hand for bone-in cuts, frozen items, or any task involving lateral force. Think of ceramic as a specialist blade, not an all-purpose cleaver. |

| Difficult to Sharpen | The extreme hardness that keeps the edge sharp also makes sharpening challenging. Normal whetstones won’t work on a ceramic blade. It requires a diamond sharpener or sending to the manufacturer’s sharpening service. DIY sharpening can be slow and tricky. | The good news: you won’t need to sharpen often. When you do, use a diamond sharpening stone or a sharpener specifically made for ceramic knives. Apply very light pressure to avoid chipping the edge. If you’re not comfortable, take advantage of manufacturer sharpening services. (For example, Kyocera offers sharpening or exchange services for their ceramic knives.) Plan ahead since you might need to mail in the knife. |

| Higher Initial Cost | Quality ceramic knives tend to cost more than entry-level steel knives. You’re also investing in a specific-use tool. A good ceramic chef’s knife from a top brand (like Kyocera) might run $40–$80 or more. And if you chip it badly, repairing or replacing can be an extra cost. | Long-term value can be high if you use it right. Consider that a ceramic knife’s edge can last many times longer than a steel one – you might save on buying new knives or sharpening services in the long run. Still, if you’re on a tight budget, factor in the potential cost of a diamond sharpener or occasional pro sharpening. Treat the knife well to avoid accidents, and it will serve you for years. |

Now, let’s explore these disadvantages with some context and tips:

Fragile Blade – Handle with Care

Ceramic knives earn both love and fear for their fragility. Simply put, if you drop a ceramic knife on a hard floor or bang it against something, there’s a high chance the blade will chip or even snap in two. This fragility is the flip side of the hardness coin – the material lacks the internal flexibility of steel. Steel might bend or dull when stressed, but ceramic will crack.

YANAGAWA (Sushi Chef): “Listen up, kid: treat a ceramic knife like your grandmother’s china. Don’t go whacking bones or coconuts with it. I’ve seen a line cook cry over his shattered ceramic blade after he tried to cut a frozen steak – snap, and it was done. Use it gently, and it’ll reward you. Abuse it, and it’s gonna break.”

Real-world examples of what not to do with a ceramic knife include: dropping it onto a tile or stone countertop, attempting to cut through a chicken bone or rack of ribs, using the blade to pry open a jar lid, or even scraping food off a cutting board with the blade sideways. These actions can all chip the fine ceramic edge or cause larger cracks. Even something as simple as cutting into an avocado and hitting the hard pit can chip a ceramic blade if you twist or force it.

To prevent heartbreak (and a potentially ruined knife), follow these tips:

- Use on Soft Targets: Stick to cutting boneless meats, vegetables, fruits, bread, and other softer foods. Avoid any item that is harder than the ceramic itself. If you wouldn’t cut it with your best razor blade, don’t cut it with ceramic.

- Soft Cutting Surface: Always use a wooden or plastic cutting board. Never cut on glass, stone, granite countertops, or metal surfaces. Hard surfaces can chip the edge on contact. A bamboo or polyethylene board will cushion the blade.

- Mind the Tip: The tip of a ceramic knife is especially vulnerable. Don’t poke or pry with it. When dicing, avoid stabbing down into the board; use a slicing motion.

- Storage: Store ceramic knives in a knife block, edge guard sleeve, or on a magnetic strip (ceramic knives will stick to magnets only if they have a steel handle or casing; many do not, so a sheath is safer). Loose in a drawer is asking for chips if it rattles around or hits other tools.

If a ceramic knife does chip a little on the edge, it’s often still usable (though those micro-chips can affect the smoothness of cuts). Larger chips or a broken tip would need professional repair (if salvageable) or replacement. The key is to prevent drops and knocks in the first place. Treat the knife with respect, and it will last a long time – but yes, it’s not as forgiving as steel.

Not a Replacement for Your Chef’s Knife (Know Its Role)

Ceramic knives are specialist tools. They excel at slicing and light cutting tasks, but they are not versatile bruisers like some steel knives. A common mistake is trying to use a ceramic knife for everything in the kitchen. That’s a quick path to disappointment.

Here are tasks unsuitable for ceramic knives, and why:

- Chopping through bones or frozen food: The force and hardness encountered will chip the blade. As Yanagawa warned, hacking a frozen steak or a bone-in chicken will likely damage a ceramic knife. Use a steel cleaver or chef’s knife for those.

- Cleaving or heavy chopping: Need to split a pumpkin or whack through a lobster shell? Use steel. Ceramic blades are thin and can fracture under heavy impact.

- Prying or twisting: Never use any knife as a pry bar, but especially not ceramic. Lateral force is the enemy of the ceramic blade – it can cause it to snap. For instance, don’t use it to pit an avocado by whacking the pit and twisting (a common technique with steel knives); a ceramic knife could chip or break doing this.

- Levering or bending: Don’t try to flex a ceramic blade to scoop food or smash garlic. It doesn’t flex – it snaps.

- High-heat exposure: While rare in normal use, note that ceramics can handle heat to a point but extreme thermal shock (like going from a hot environment to cold water) could possibly affect them. This isn’t usually an issue in cooking, since you won’t stick your knife in a flame, but avoid weird uses like stirring a hot pot with the blade.

Essentially, steel knives remain better all-purpose tools. Chefs typically use a combination: perhaps a ceramic knife for fine slicing and a trusty steel knife for heavy lifting. Likewise, an outdoorsperson might pack a ceramic knife for food prep but also carry a sturdy steel survival knife for chopping wood or cutting thick rope.

Think of a ceramic knife as a scalpel or precision slicer. For what it does well – slicing boneless meats, vegetables, fruits – it does extremely well, with that light touch and sharp edge. For everything else (from butchery to bushcraft), stick to steel blades designed for those stresses.

Special Sharpening Needs

One question people often ask: “Do you ever need to sharpen a ceramic knife? If so, how?” The answer is yes – eventually the blade may dull slightly or develop tiny chips that you’ll want to smooth out. However, sharpening ceramic is not as simple as sharpening steel.

Why you can’t use a regular knife sharpener: Typical pull-through sharpeners or whetstones (~1000 grit) are made to remove metal, which is much softer than the abrasive. Zirconia ceramic is so hard that standard aluminum oxide stones barely scratch it. You’ll just wear out your stone or sharpener without effectively grinding the ceramic blade.

The proper way to sharpen a ceramic knife is to use a diamond abrasive. Diamond sharpening stones or diamond-coated grinding wheels are hard enough to cut into the ceramic material. Some electric sharpeners have diamond wheels specifically for ceramic knives. You can also send the knife back to the manufacturer or a sharpening service; many knife companies that sell ceramic knives (including Kyocera) offer sharpening for their products.

If you choose to sharpen it yourself with a diamond stone, here are tips:

- Use light pressure: Let the diamonds do the work. Pressing hard can cause the brittle edge to chip instead of smoothly grinding. Gentle, consistent strokes at the correct angle (usually around 15–20 degrees per side) work best.

- Patience is key: Ceramic is slow to grind. It might take longer than you expect to refresh the edge, especially if there are chips to remove. Take your time and periodically check progress.

- Avoid cheap pull-through “ceramic sharpeners”: There are some gadgets marketed for ceramic knives, but if they don’t use diamond abrasives, they likely won’t work. Stick to known diamond sharpening tools.

- Professional service: If you’re not confident, it’s perfectly fine to use a professional service. Kyocera, for example, will sharpen or replace blades (sometimes for a small fee or even free in certain warranty cases). The downside is being without your knife for a few days or weeks during shipping. But you’ll get it back factory-sharp.

The good news is that, because ceramic knives hold an edge so long, you’ll rarely need sharpening. Some home users go 5+ years without sharpening their ceramic knives and still find them adequately sharp for cooking. When the time does come, just remember it requires different equipment. Under no circumstances try to “sharpen” a ceramic knife on a normal kitchen honing steel – those rods are far too soft and can even cause micro-chipping. And never try to use a cheap grinder or file; you’ll likely damage the blade (and possibly send ceramic dust everywhere, which isn’t great to breathe).

In summary, sharpening a ceramic knife is a special task – not difficult with the right tool, but not as straightforward as honing a steel blade. Plan for that, and your ceramic knife can essentially last indefinitely, since you can refresh the edge when needed.

Cost Considerations

When ceramic knives first hit the market (around the mid-1980s, introduced by Kyocera in Japan), they were quite expensive and considered almost a luxury item. Prices have come down since, but a quality ceramic knife still costs more than an average stainless steel kitchen knife. Why? The manufacturing process is more involved (sintering, precision grinding with diamonds) and relatively lower-volume than mass-produced steel knives.

For example, a mid-range 6-inch ceramic chef’s knife might cost $50, whereas you can find a decent stainless equivalent for $30. High-end ceramic knives or larger blades (like an 8-inch ceramic slicing knife) can be $100+. There are inexpensive ceramic knives on the market, but be wary – extremely cheap ones may use lower-grade ceramic that is more prone to chipping (or they might have quality control issues with the edge grind). It’s often worth investing in a reputable brand.

YUKIKO: “I hesitated at the price at first. A ceramic knife cost a bit more than my usual knife. But I realized that if it stays sharp longer, I won’t need to replace or sharpen it as often – in the long run, that actually saves money. For me, the convenience was worth the upfront cost.”

Indeed, many users find that the long-term value is good. Since the blade doesn’t wear out quickly, you’re not buying new knives frequently. Also, you won’t spend as much time or money sharpening (no need for honing steels or multiple whetstones, maybe just the occasional professional sharpening). One could argue that a $50 ceramic knife that lasts 5+ years without much maintenance is cheaper than going through several $20 steel knives in the same period or paying a sharpening service regularly for your steel knife.

However, consider the extra costs: if you don’t already have a diamond sharpener and plan to sharpen yourself, that’s an additional purchase (diamond stones can be $30 and up). Or if you plan to use manufacturer sharpening services, there may be shipping costs. And if a ceramic knife does suffer a big chip or break, repairing or replacing it is an added expense (whereas a steel knife might be more salvageable).

The key is to match the purchase to your needs. If the advantages align with your cooking or outdoor activities, the cost is justified. But if you rarely cook or are prone to dropping knives, you might not get your money’s worth from a ceramic blade.

To sum up: ceramic knives are an investment. They’re not outrageously expensive, but they cost more than run-of-the-mill knives. With proper use, they repay you in durability and performance. Just go in knowing that you’re paying for a specialized tool, and treat it accordingly.

Ceramic Knife vs Steel Knife: Key Differences

You might be wondering how ceramic knives stack up directly against the traditional steel knives in various aspects. Let’s compare them head-to-head on several important factors:

| Aspect | Ceramic Knife | Steel Knife |

|---|---|---|

| Material | Zirconium oxide ceramic (ultra-hard zirconia). Non-metallic. | Steel (an alloy of iron, carbon, and other elements). |

| Hardness | Extremely hard (~8.5 Mohs). Harder than virtually any steel. | Varies by grade: common stainless ~4.5 Mohs; high-carbon steels ~7.5–8 Mohs. Hard, but generally softer than ceramic. |

| Toughness | Brittle. Will crack or chip if bent or impacted. Doesn’t flex under stress. | Tougher. Can often bend slightly or dent rather than shatter. Quality steel has high fracture toughness – it can take some abuse (within reason). |

| Weight | Lightweight. Often ~50% of the weight of a similar-sized steel knife. Feels nimble, but less heft. | Heavier. Steel is dense, and many knives have full tangs/bolsters adding weight. Some cooks prefer the heft for momentum in chopping. |

| Sharpness & Edge | Razor-sharp initial edge, ground at factory with diamond wheels. Stays sharp a very long time without honing. Edge is usually a bit thicker (to support the brittle material) but very keen. | Can be extremely sharp when freshly honed (Japanese carbon steel knives are among the sharpest tools). However, regular use dulls the edge faster – requires honing and sharpening periodically to maintain peak sharpness. |

| Edge Retention | Outstanding. Keeps cutting edge 10× (or more) longer than typical steel. Rarely needs sharpening in normal use. | Variable. Good high-carbon steel holds an edge well but still needs regular maintenance (honing after each use, sharpening every few weeks or months depending on use). Softer stainless steel dulls quickly. |

| Corrosion Resistance | 100% rust-proof. Will not corrode or pit, even with exposure to acids, salts, or moisture. No special care needed to prevent rust. | Depends on steel type. Carbon steel can rust easily if not dried and oiled. Stainless steel resists rust but can still corrode in harsh conditions or if neglected. Requires some care (keep dry, occasionally oil carbon steel). |

| Reactivity | Non-reactive. Won’t discolor foods or impart any taste/odor. No patina forms. Knife stays inert with any ingredient. | Can react. Carbon steel can impart a metallic taste or make onions/fruit brown due to iron. Stainless is mostly non-reactive, though mild effects can occur with some foods. Carbon steel blades often develop a patina (harmless, but a form of reactivity). |

| Maintenance | Low maintenance for sharpness (no frequent honing). High maintenance for sharpening (needs diamond tools or service when required). Must handle carefully to avoid chips (so in that sense, need mindful use). | Regular maintenance needed for sharpness (use a honing steel often; sharpen on whetstone or sharpener as needed). Easy to sharpen at home with common tools. Generally more forgiving if you use it a bit roughly (you can often hone out small rolls on the edge). |

| Versatility | Specialist. Best at straight slicing of softer materials. Not suited to twisting, prying, or cutting extremely hard items. Limited to kitchen prep and some field tasks like cutting rope or cloth. | All-purpose. A good steel knife can perform in many roles: chopping, slicing, carving, even light prying or twisting if it’s a robust blade. There’s a steel knife for every task (from chef’s knives to axes). |

| Stealth & Non-Detectability | Undetectable by metal detectors (if knife has no metal parts). Non-magnetic and non-conductive. This can be a tactical advantage (for lawful uses like bomb disposal) but also a security concern (illegal to carry on planes, etc.). | Triggers metal detectors (it’s metal, after all). Magnetic and conducts electricity. No stealth advantage – readily detected by standard security. (Some specialized non-magnetic steel exists, but not common for knives.) |

| Lifespan | Very long lifespan if cared for. The blade won’t corrode or wear much. However, a major drop could end its life suddenly. Many come with serviceable life until chipped/broken, which might be years. | Very long lifespan if cared for as well. Steel knives can be sharpened indefinitely until they’re ground away after decades. They can also often be repaired (e.g., a bent tip can be re-ground). A steel knife might survive impacts that would destroy a ceramic. |

In short, ceramic vs steel is not about which is “better” overall – it’s about which is better for a given purpose. Ceramic knives excel at precision slicing with minimal maintenance, whereas steel knives offer versatility and robustness. Many chefs and outdoorsmen choose to own both, using each for what it does best.

For instance, you might use a steel chef’s knife for heavy chopping and a ceramic knife for fine slicing and garnish work. Or carry a steel survival knife for building camp and a small ceramic knife for preparing food. Understanding these differences allows you to get the most out of your ceramic knife without expecting it to perform feats it wasn’t designed for.

YUKIKO: “In my kitchen, I reach for my ceramic knife when I want beautiful, thin slices of vegetables or fruits – especially for salads and presentation. But I still use my sturdy steel knives for carving a roast or cutting through squash. Each has its place.”

GENSAKU: “Different knives for different jobs – that’s the way of the craftsman. Embrace the ceramic knife for what it’s great at, and you’ll be rewarded. Try to make it do your heavy butchery, and you’ll be reaching for the broom to sweep up ceramic bits!”

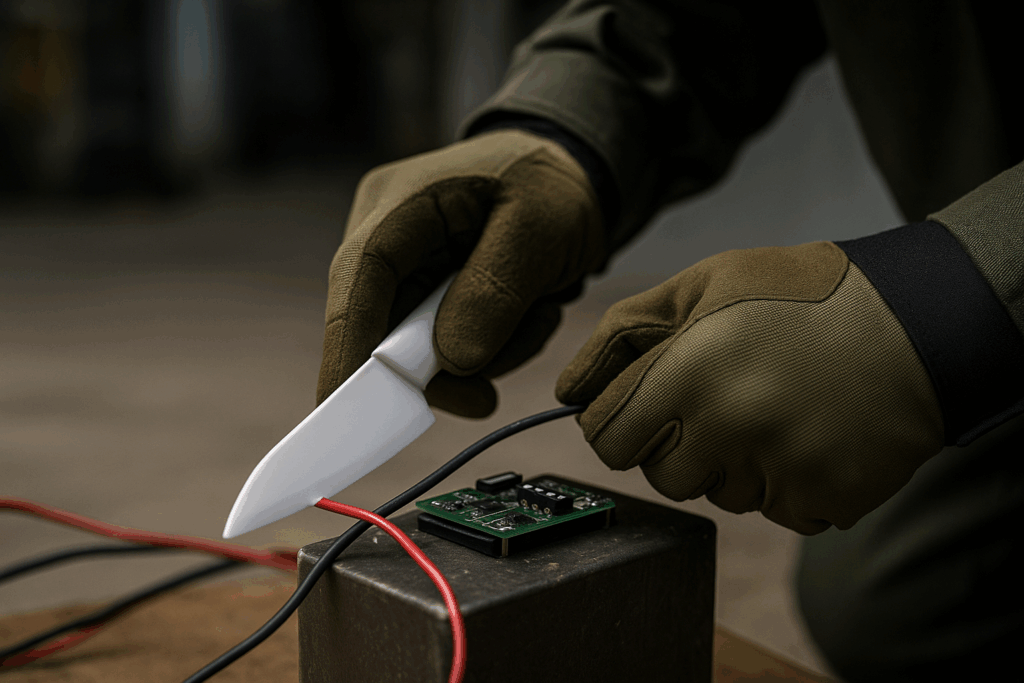

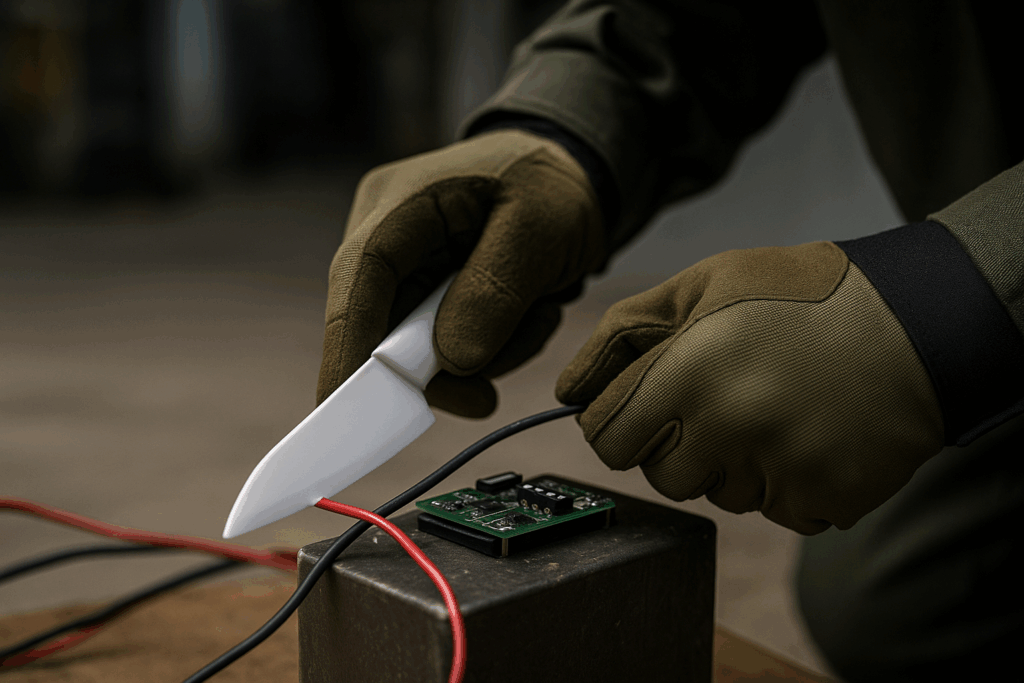

Outdoor and Tactical Uses of Ceramic Knives

Ceramic knives aren’t confined to the home kitchen. Their unique properties have also caught the interest of outdoor enthusiasts, military personnel, and survivalists. There are even “tactical ceramic knives” marketed for law enforcement and EOD (Explosive Ordnance Disposal) teams. Let’s explore how ceramic blades are used outside of a typical kitchen, and what advantages (and challenges) they bring in these contexts.

A folding ceramic tactical knife (Böker Plus Anti-Grav) with a zirconia blade and carbon fiber handle. This ultra-light folder weighs just 2.1 oz, making it ideal for everyday carry without burden. Outdoor users appreciate the combination of a rust-proof, non-magnetic blade and the strength of modern handle materials in knives like this.

In the Field: Camping, Hiking, and Survival

For campers and hikers, two qualities of ceramic knives stand out: light weight and no rust. We’ve touched on weight – carrying a 1–2 ounce knife that can capably handle your cooking prep is a big win when you’re backpacking. You can have a knife to slice salami, cheese, or fruit on the trail without adding much load. Many ceramic outdoor knives are designed as folding knives or small fixed blades that tuck easily into gear.

However, when it comes to survival or bushcraft tasks, ceramic knives have limitations outdoors just as in the kitchen. You wouldn’t want a ceramic knife as your primary tool for building shelter, batoning wood for a fire, or other heavy-duty camp chores. Those tasks require toughness and durability (usually a full-tang steel knife or machete). In a survival kit, a ceramic knife could serve as a backup blade for food prep or as a super lightweight contingency knife, but you’d still rely on a steel blade for major cutting and chopping tasks.

There is one interesting niche use: non-sparking blades. Ceramic knives do not produce sparks when striking other materials (no metal on metal contact). For people working in environments with flammable gases or materials, a non-sparking tool is valuable. For example, some miners or hazmat workers might use ceramic or other non-sparking knives to cut materials without risk of igniting a spark.

Tactical and Security Applications

Ceramic knives have gained a bit of notoriety in the tactical realm, partly because of their ability to pass metal detectors. A fully ceramic blade with a plastic or G10 handle can go through a metal detector without triggering it. This has obvious security implications – in fact, it’s illegal to carry knives (metal or ceramic) through airport security, and the TSA will confiscate a ceramic knife just as readily as a metal one. So, while the non-detectability is true, attempting to exploit that for unlawful purposes is a very bad idea (and in many jurisdictions, possession of an undetectable knife can itself be illegal).

That said, there are lawful tactical uses for ceramic blades:

- EOD (Bomb Squad) Operations: Bomb technicians sometimes use ceramic knives when disarming explosive devices. The reason is two-fold: ceramic blades are non-conductive (they won’t conduct electricity) and non-magnetic. If a bomb has electrical components or magnetic triggers, using a metal tool could create a spark or magnetic field that sets it off. A ceramic blade can cut wires without risk of shorting anything, making it a safer choice in that scenario. Many EOD units issue ceramic knives for cutting detonator wires or other sensitive tasks where metal tools pose a hazard.

- Policing and Corrections: Some law enforcement officers have used small ceramic knives as last-ditch backup weapons or tools, since they can be very easily concealed due to their thin profile and lack of metal. In corrections (prison) environments, metal detectors are used to detect weapons – a ceramic shiv would not be picked up. Obviously, this is more a concern for security (to prevent inmates from getting such items), but it also explains why the existence of ceramic knives requires security protocols beyond just metal detectors (e.g. visual inspection, x-rays).

- EMT/Rescue: A ceramic knife can be useful for responders who need a blade in MRI rooms or other high-magnetic environments where metal objects are not allowed. For instance, there are ceramic safety knives for cutting clothing or seatbelts off accident victims in MRI facilities, since they won’t be yanked by the powerful magnets like steel would.

From a self-defense perspective, some companies market ceramic “stealth” knives, but one must be extremely careful with legal and practical considerations. Yes, a ceramic knife could theoretically be carried through certain detectors, but using it for self-defense has downsides: it’s brittle (could break if it strikes a hard object like a bone or a belt buckle) and it generally doesn’t have the blade mass or design to serve as a fighting knife. Plus, if one were to use such a knife illegally, they’d face serious charges. In short: the tactical advantages of ceramic knives are relevant in very specific professional contexts, not so much for the average person’s self-defense.

YANAGAWA: “I had a friend in the JSDF (Japan’s Self Defense Force) – he said they sometimes carried ceramic knives for certain ops because they’re so light and non-magnetic. But he also told me: ‘This is a tool, not a weapon. If I need to pry a door or defend myself, I’m switching to steel.’ That stuck with me. Use each tool for its intended use.”

Limitations in the Field

We must reiterate the limitations: if you try to use a ceramic knife to chop wood for a fire or as a screwdriver or to pry open ammo crates, you’re going to end up with a broken knife. Outdoors, the same rules apply: use ceramic knives for cutting only, and preferably slicing (straight down or draw cuts). Do not hammer on the spine (a common bushcraft technique with steel knives called “batoning” to split wood) – the ceramic will likely crack. Do not throw a ceramic knife (it will break).

Also, keep in mind sharpening in the field is virtually impossible unless you carry a diamond sharpener. Steel knives you can sharpen on a variety of stones or even improvised means if needed, but ceramic needs that diamond surface. The flip side is you probably won’t need to sharpen it during a typical trip because it stays sharp so long, but if you somehow dulled or nicked it, you’d be out of luck until you got home.

Outdoor Use Summary

For the outdoors and tactical domain, ceramic knives fill niche roles:

- They make excellent camp kitchen knives – light, sanitary, no rust.

- Good for fishing/boating – you can even use them as dive knives (though prying a stuck spear tip with a ceramic knife would be a bad idea).

- Useful for specialty tactical uses like EOD where non-conductivity and non-magnetism are crucial.

- They are ultra-portable backups or concealable tools, but come with legal and practical caveats.

Most outdoorspeople will carry a ceramic knife as a secondary utility knife rather than their primary survival knife. Think of it as an extension of your cooking gear in the wild, not as part of your axe or heavy-knife toolkit. If you use it within its limits, it can be a fantastic addition to your pack.

Care and Maintenance Tips for Ceramic Knives

Taking care of a ceramic knife is straightforward, but it does require a slightly different mindset than caring for steel knives. Here are some practical tips to keep your ceramic blade in top shape for the long haul:

- Use the Right Cutting Surface: Always cut on wood or plastic cutting boards. Avoid glass, granite, marble, or tile surfaces. Even a porcelain plate can be hard enough to chip a ceramic knife’s edge. (If you have ceramic steak knives, try not to scrape them aggressively on ceramic plates when cutting your steak – use a gentle sawing motion and don’t press down onto the plate.)

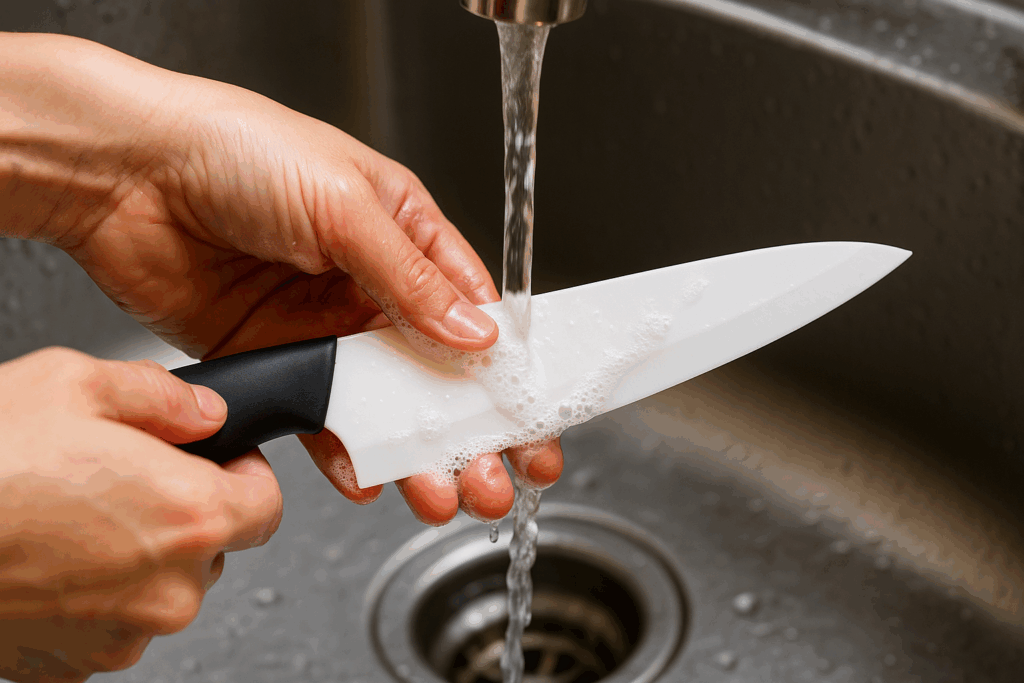

- Hand Wash Only: It’s best to wash ceramic knives by hand in the sink. While the material itself won’t be harmed by dishwasher detergent, the machine jostling can bang the knife against other utensils or the rack, causing chips. Washing by hand in soapy water and immediately drying with a soft cloth is ideal. Luckily, since ceramic doesn’t rust, you don’t have to immediately dry it for fear of corrosion – but you should dry it to avoid water spots and for safety (a wet knife can slip when handling).

- Safe Storage: Store your ceramic knife so that the blade is protected. Many ceramic knives come with a sleeve or sheath for this reason. In a knife block, make sure it slots in without grinding on anything. On a magnetic strip, ensure the magnet is strong enough – some ceramic knives have steel inside the handle which allows magnetic storage; if not, use an alternative storage. Keeping it separate also ensures it won’t hit other knives (preventing chipping and protecting your other knife edges, since ceramic can actually scratch steel).

- Avoid Dropping: This may sound obvious (no one intends to drop knives), but accidents happen. Try to handle the knife with dry hands and focus – the worst case is dropping it onto a hard kitchen floor. Consider putting a rubber mat or towel on your countertop where you prep if you’re especially concerned; it can cushion a fall if the knife slips off the cutting board. When carrying the knife around the kitchen or campsite, do so with care.

- Cut Straight: Use straight slicing or chopping motions, not twisting. If something doesn’t cut through with a straight slice, don’t apply lateral pressure – use a steel knife for that task instead.

- Check Edges Periodically: Every so often, examine the blade in good light. If you notice tiny chips (“micro-chipping”) along the edge, you might tune them out by using a fine diamond sharpener gently just to smooth the edge. If there’s a larger chip, you may decide to have it professionally addressed. Using a chipped ceramic knife won’t poison your food or anything, but the cuts will not be as smooth and it could worsen if not attended to.

- Transport with Care: If you take a ceramic knife in a knife roll or backpack, ensure it’s in a protective case or sheath. Bouncing around in a bag can be as bad as dropping it.

- No prying or cutting bone (again!): It’s worth repeating because a common way people accidentally break knives is by forgetting they have the ceramic knife in hand and doing something they’d normally do with a steel knife, like trying to separate frozen burger patties or carve a chicken leg. Train yourself: ceramic knife = slicing only.

If the worst happens and your knife chips or breaks, handle the pieces carefully. Ceramic shards can be very sharp (just like broken glass). Dispose of broken pieces in a wrapped container so they don’t cut through a trash bag. Some manufacturers will replace a blade for a fee if you send the broken one in (Kyocera, for instance, has a program for blade replacement at a lower cost than a new knife in some cases). If it’s a small chip on the edge, a professional sharpening service can sometimes grind out the chip and salvage the knife, slightly shortening the blade but saving it.

On the flip side, here are things you don’t have to worry about with a ceramic knife (enjoy these conveniences!):

- No oiling or special rust prevention. Forgot to dry it? No problem – it won’t rust or pit.

- No honing before each use. Unlike high-carbon steel knives that benefit from a quick honing steel session to straighten the edge, a ceramic knife’s edge doesn’t bend. You can just grab it and use it; it either is sharp or it needs a full sharpening, nothing in between. Day to day, it’s maintenance-free.

- No worries about dishwasher detergent corrosion. With steel knives, harsh dishwasher soap can dull the blade or cause stains. Ceramic is chemically very stable, so it’s unaffected by detergents or mild acids/bases in foods.

By following these care guidelines, a ceramic knife can literally last a lifetime of home use. They often only meet their end by accidental dropping or misuse, not by wearing out. In fact, some experienced users have noted that the handle or glue joint might fail before the blade ever does! (Quality brands have durable handles, but cheaper ones have plastic handles that might crack over many years.) Treat both the handle and blade gently.

YUKIKO: “I’ve had my ceramic kitchen knife for 3 years now. I use it daily and honestly give it very little thought – I wash it, I put it back in its sleeve, that’s it. It still slices like day one. The key was learning what not to do with it. Once you avoid the big no-nos (like no bones, no flexing), it’s one of the easiest knives to own.”

Kyocera – The Leading Brand in Ceramic Knives

It’s hard to talk about ceramic knives without mentioning Kyocera. The Japanese company Kyocera (Kyoto Ceramic Company) was a pioneer in commercial ceramic cutlery.

In fact, they introduced the world’s first ceramic kitchen knife in the 1980s and have been the market leader in this category since. Many people first hear about ceramic knives through Kyocera’s products, and the brand has become almost synonymous with ceramic knives (much like “Xerox” for copiers or “Tupperware” for plastic containers).

A Brief Overview of Kyocera’s Ceramic Knives

Kyocera is a large ceramics and electronics company, so they leverage a lot of advanced materials science in making knives. Their blades are made from proprietary zirconia-based ceramics – you’ll often see model numbers like “Z206” for their specific zirconia formula.

Over the years, they’ve improved the toughness of their ceramic to reduce chipping while maintaining hardness. Kyocera offers both white-bladed knives and black-bladed knives. The black blades are made from a hotter firing process and are advertised to be slightly harder (and they carry a higher price, often). Aesthetically, the white blades have a clean, hygienic look, while black blades look sleek and don’t show stains at all (not that ceramic stains much anyway).

Blade design: Kyocera and other top brands have refined the edge geometry of ceramic knives. They grind very sharp edges, but they usually don’t make them as thin as ultra-fine steel edges, because they know too thin would be too fragile. The result is an edge that’s extremely sharp but also micro-serrated in some models (especially their serrated or micro-serrated steak knives). For example, Kyocera makes ceramic steak knives with micro-serrations that cut meat easily but still won’t tear it.

Handle design: Many Kyocera knives feature comfortable, ergonomic handles made of lightweight polymers. They often have a tang that’s molded into the handle. The handles come in various colors (sometimes Kyocera knives are known by their vibrant handles, from red to green to black). They focus on balance and grip, knowing that a lighter knife still needs good handle control. Users often comment that Kyocera’s knives “feel right” in the hand due to the handle shape and light weight combination.

Support and service: One of Kyocera’s big selling points is their customer support for knife owners. They typically offer sharpening and repair services. For instance, in the US, Kyocera will sharpen your ceramic knife for a small fee (or sometimes complimentary for the first time) if you mail it to them. If the blade is badly chipped, they might replace it for a reduced cost. This kind of support gives buyers confidence, because one concern with ceramic knives is “what if it chips?” – with Kyocera, you have the option to get it fixed properly by the experts.

Reputation: Kyocera’s ceramic knives have a strong reputation for quality and consistency. They are often reviewed as having the best edge retention and overall finish. As a result, they do tend to be priced a bit higher than off-brand ceramic knives. Many cooking enthusiasts and chefs who use ceramic will specifically choose Kyocera for peace of mind. There are other notable brands too (for example, Böker in Germany makes some ceramic tactical knives, and some brands like Cuisinart have ceramic-coated knives which are different – those are steel with ceramic coating, not full ceramic). But in the realm of true ceramic blades, Kyocera is the dominant name.

YUKIKO: “My first ceramic knife was a Kyocera. It came with a little card about their sharpening service, which made me feel secure. Also, I accidentally dropped it once (yes, I confess). The tip broke. I was heartbroken, but I contacted Kyocera and they actually replaced the blade at a reasonable cost. That kind of service made me a loyal customer. I now have a set, including their ceramic paring knife and utility knife, and I use them daily.”

Kyocera’s innovations since the 80s have gradually addressed some weaknesses of ceramic knives. They worked on improving toughness (though any ceramic will still be more brittle than steel). They also introduced different lines: for example, a “professional” series that’s heavier with thicker spines for slight added durability, and more economical series for casual home cooks.

It’s worth noting that Kyocera even expanded into ceramic mandoline slicers, peelers, and other kitchen tools, capitalizing on the advantages of ceramic cutting surfaces (sharp and won’t rust). They clearly believe in the material’s benefits across kitchen tasks.

For those considering buying a ceramic knife, going with a reputable brand like Kyocera (or others such as Shun’s limited ceramic line, Miyabi, or Zwilling if available) can ensure you get a well-made product. They might cost a bit more upfront, but as we discussed in the cost section, you often get what you pay for in terms of blade quality and support.

In summary, Kyocera has played a huge role in popularizing ceramic knives worldwide. Their knives exemplify the strengths of ceramic blades – sharpness, lightness, and longevity – while minimizing the downsides through good design and service. While we won’t dive into specific product recommendations here (that’s a topic for another article), it’s safe to say that Kyocera is a trusted choice if you’re venturing into the world of ceramic cutlery.

Conclusion

Ceramic knives have proven themselves to be a valuable addition to the cutlery arsenal for both chefs and outdoor enthusiasts. They offer distinct strengths that traditional steel knives cannot:

- No Rust, Ever: A ceramic knife can make rust worries a thing of the past. Cut acidic foods or use it in wet environments with zero concern about corrosion – a huge relief and convenience in both professional kitchens and on camping trips.

- Feather-Light Handling: The almost weightless feel of a ceramic blade can turn tedious prep work into a more enjoyable task. When your knife is light and agile, you might find yourself slicing and dicing with a bit more spring in your step (and certainly less ache in your wrist after a long session).

- Lasting Sharpness: For those who value a razor-sharp edge but dislike frequent sharpening, ceramic knives are a dream come true. They stay sharp far longer and keep performing cut after cut. Your vegetables will have clean, precise edges and your cuts will be effortless, which in turn can lead to prettier presentations and maybe even a boost in your cooking motivation.

On the other hand, ceramic knives do come with trade-offs that require mindful use:

- They are prone to chipping or breaking if misused – you can’t treat them carelessly or use them for every task.

- They are specialized – think of them as a scalpel rather than a cleaver. For many jobs, you’ll still want a good steel knife at hand.

- Sharpening, when eventually needed, takes a bit of planning – but it’s infrequent and very achievable with the right tools or services.

For chefs, a ceramic knife can become the go-to tool for tasks like slicing fruits for dessert, chiffonading herbs without browning them, or portioning fish for sashimi with surgical precision. It’s a knife that can elevate the finesse of your work. For outdoor enthusiasts, a small ceramic knife in your kit means you always have a reliable cutter for food and basic camp needs that won’t rust away or weigh you down.

YANAGAWA: “I always say, use the right knife for the right job. The ceramic knife has earned its place on my cutting board for those jobs it does better than anything – slicing cucumber so thin you can read through it, or cleanly quartering a persimmon without staining. But when I need to break down a chicken, I set it aside and pick up the heavy steel. Wisdom is knowing when to use which tool.”

In the end, adopting a ceramic knife is about enhancing your cutting experience. Many who were initially skeptical (“can it really cut?”) find themselves pleasantly surprised (“it cuts beautifully!”). The first time you draw a ceramic blade through a ripe tomato and see it fall apart into perfect slices with no crushing, you might just grin from ear to ear.

If you’ve ever been frustrated by knives that dull too quickly, or if you’re intrigued by the idea of a blade that marries space-age material with everyday utility, give a ceramic knife a try. Chefs might discover a new favorite for prep work, and outdoor adventurers might appreciate a blade that stands up to the elements. Just remember the golden rules of ceramic knife care, and you’ll likely wonder how you managed so long without one.

In conclusion, ceramic knives are a testament to modern materials science improving our culinary and outdoor tools. They emphasize sharpness, purity, and ease, at the cost of requiring some care and discretion in use. For many tasks, they truly shine. As technology and craftsmanship continue to improve (who knows, we might see even tougher ceramic composites in the future), the gap between steel and ceramic will only narrow further.

Whether you’re slicing sushi in a restaurant, chopping salads at home, or cutting fruit by the campfire, a ceramic knife can be a game-changer. Embrace its strengths, respect its limits, and you’ll be rewarded with a knife that is a joy to use. Happy slicing!

Comments